Jib cranes are built to last—many units operate reliably for 10, 15, even 25+ years. But just because a crane still moves and lifts doesn’t mean it’s still safe to lift at its original rating. In real industrial environments, age, wear, load cycles, repairs, modifications, corrosion, and changing operational demands can all gradually alter how a crane performs under stress. That’s why reassessing jib crane load capacity is not just a good maintenance practice—it’s often essential for safety, compliance, and operational efficiency. If you operate an older jib crane in manufacturing, logistics, construction, fabrication, or heavy industry, this article will explain exactly why capacity reassessment matters, what triggers a reassessment, and how to do it properly.

Table of Contents

ToggleUnderstanding Jib Crane Load Capacity (And Why It Changes Over Time)

Jib crane load capacity refers to the maximum weight a jib crane can lift safely under normal operating conditions. This rating is established by the manufacturer based on:

- Structural design (boom, mast, brackets, base plate)

- Material strength

- Hoist and trolley capacity

- Load distribution and stability

- Safety margins built into design standards

- Controlled testing and verification

In theory, the rated load stays constant. In real life, the crane’s condition changes—and when condition changes, the risk of structural failure and unsafe lifting increases.

When you reassess capacity, you’re asking a crucial question:

“Can this jib crane still safely lift at its rated load today?”

7 Key Reasons Old Jib Crane Load Capacity Must Be Reassessed

1) Metal Fatigue from Load Cycles (The Hidden Capacity Killer)

Most cranes fail gradually, not suddenly. Over time, the crane experiences repeated stress from lifting loads. Even if each lift stays within rated capacity, tens of thousands of cycles can create fatigue.

Fatigue damage tends to appear in:

- boom weld joints

- mast-to-base connection

- wall bracket points (wall-mounted cranes)

- pin joints (articulated jibs)

- trolley travel area

This fatigue reduces structural reliability. The crane may still lift, but it may no longer handle the same load safely under dynamic conditions.

✅ Reassessment ensures the crane still meets rated performance after years of lifting cycles.

2) Corrosion, Rust, and Environmental Degradation

Older jib cranes often operate in harsh environments:

- coastal or humid areas

- chemical processing zones

- dusty fabrication workshops

- outdoor yards

- food, marine, or industrial washdown spaces

Corrosion reduces effective metal thickness and weakens the crane’s load-bearing structure. What was once a strong boom section may now have reduced strength—especially if rust appears around weld seams or bracket plates.

Even surface-level corrosion can hide deeper section loss.

✅ Capacity reassessment helps confirm whether corrosion has reduced the crane’s original load-bearing ability.

3) Structural Modifications and Repairs That Alter Load Paths

One of the most common reasons older cranes need reassessment is modification.

Examples include:

- replacing the hoist with a heavier model

- adding a different trolley style

- extending the boom

- adjusting mounting brackets

- welding repairs after damage

- reinforcing parts without engineering verification

Even well-intended modifications can change how forces travel through the crane. If the load path changes, the original rating may no longer apply.

✅ Reassessment verifies that changes haven’t compromised jib crane load capacity.

4) Foundation and Mounting Integrity Changes Over Time

A jib crane is only as strong as its mounting structure.

Floor-mounted cranes rely on:

- reinforced concrete thickness

- base plate alignment

- anchor bolt torque integrity

- settlement resistance

Wall-mounted cranes rely on:

- wall/column load-bearing strength

- bracket anchoring

- structural stability of the building itself

Over years, buildings settle, concrete cracks, bolts loosen, and vibration stress accumulates. Even small shifts can affect crane stability and increase deflection during lifting.

✅ A reassessment includes verifying the mounting structure can still support the rated load.

5) Wear of Hoist, Brake, Chain, Rope, and Trolley Components

A crane can appear structurally fine but become unsafe due to hoist or lifting media wear.

Common age-related issues include:

- brake slippage

- gear wear

- electrical control drift

- chain stretch

- wire rope fraying

- hook throat opening

- trolley wheel misalignment

These issues reduce safe lifting performance, which directly affects jib crane load capacity in practice.

✅ Reassessment ensures the crane can still safely lift, hold, and lower loads at rated limits.

To understand how maintenance supports consistent capacity, read:

👉 What Jib Crane Load Capacity Depends on Proper Maintenance

6) Changing Workloads and New Operational Demands

A crane installed 10 years ago may have been designed for:

- occasional lifting

- moderate loads

- low duty cycle

But businesses evolve. New machinery, new material sizes, higher production volume, or heavier loads may appear—sometimes gradually.

Even if you never exceed the rated capacity, the crane’s duty class suitability may no longer match how often it’s used.

If your operations now involve:

- higher lift frequency

- heavier average loads

- more rotation and travel under load

- continuous multi-shift operation

…then the original crane configuration may no longer be suitable.

✅ Reassessment ensures your crane rating aligns with real, modern use.

7) Compliance, Audits, and Inspection Requirements

In many regions, lifting equipment must be:

- tested periodically

- certified at defined intervals

- documented for compliance

- reassessed after repairs or modifications

Even if regulations vary (OSHA, ANSI, ASME, ISO, local standards), one principle remains consistent:

Older lifting equipment requires documented verification to remain compliant.

Reassessing capacity protects the business from liability and ensures safe operations.

This topic ties closely to Safe Working Load and capacity rules. Learn more here:

👉 How Jib Crane Load Capacity Relates to Safe Working Load

Warning Signs Your Old Jib Crane Needs Capacity Reassessment Now

If you notice any of the following, reassessment shouldn’t wait:

- visible cracks, rust, or deformation on boom/mast

- unusual creaking or grinding under load

- increased boom deflection

- hoist brake slipping or delayed stopping

- overload alarms triggering more often

- loose base bolts or wall bracket movement

- sudden increase in load swing

- changes in rotation smoothness

Also reassess immediately if:

✅ the crane has been overloaded (even once)

✅ the hoist or trolley was upgraded

✅ the crane was repaired after damage

✅ your facility structure changed

✅ the crane has been moved or reinstalled

If overload is suspected, this guide is essential:

👉 What If Jib Crane Load Capacity Is Exceeded

How Engineers Reassess Jib Crane Load Capacity (Step-by-Step)

Reassessment should be done by qualified professionals or certified inspectors. A typical process includes:

Step 1: Review Documentation & Nameplate Data

- manufacturer’s rated load

- crane model and serial number

- original design conditions

- previous inspections and load tests

Step 2: Structural Inspection and NDT (If Needed)

- inspect welds and joints

- check boom and mast alignment

- look for corrosion and section loss

- evaluate anchor points

- perform non-destructive testing (ultrasonic, dye penetrant) when cracking is suspected

Step 3: Hoist and Lifting Media Verification

- brake load holding test

- chain/rope condition check

- hook deformation check

- hoist motor and gearbox condition

Step 4: Load Testing Under Controlled Conditions

This verifies real performance. Load tests may include:

- rated load lift test

- stability and swing tests

- rotation under load

- trolley travel under load

- emergency stop and limit switch validation

Step 5: Re-rating or Approval

Based on findings, the crane may be:

- approved at original capacity

- approved with maintenance/repairs required

- re-rated to a lower capacity

- removed from service until corrected

Special Notes for Wall-Mounted and Articulated Jib Cranes

Wall-Mounted Cranes

These cranes depend entirely on building structure integrity. Older buildings or modified structural supports create risk.

Reassessment must verify:

- wall bracket anchoring strength

- column/wall integrity

- deformation around mounting point

- structural design suitability

Articulated Jib Cranes

Articulated cranes include joints and multiple pivot points, so reassessment should also include:

- joint bushing wear

- pin and bearing play

- alignment across both arms

- rotation smoothness

If you’re considering modern wall-mounted options that support space-saving workflows, explore:

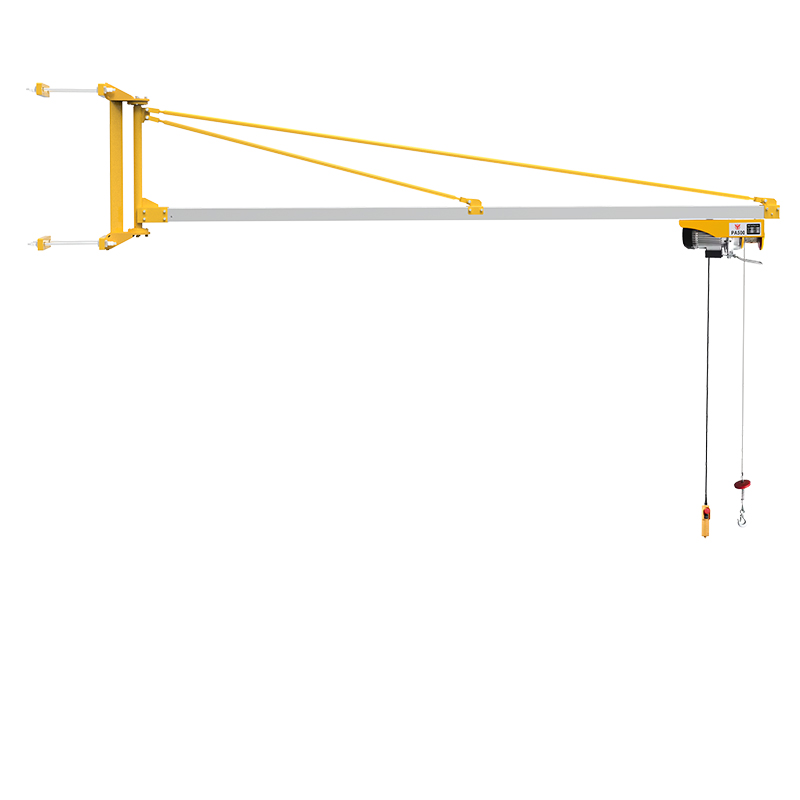

👉 Articulated Jib Crane – Wall Mounted

And for additional jib crane models and variations:

👉 more crane products

SEO-Friendly FAQ: Old Jib Crane Load Capacity Reassessment

How often should jib crane load capacity be reassessed?

Typically every 12 months through inspection and testing—more often for heavy-duty usage, harsh environments, or high-cycle lifting.

Can an old crane still lift its rated load safely?

Yes—but only if structural condition, hoist performance, and mounting integrity remain verified through inspection and load testing.

Does repainting and cosmetic repair restore load capacity?

No. Cosmetic improvements don’t correct fatigue, corrosion loss, or mechanical wear.

What happens if the crane is re-rated to a lower load?

The crane can still be used safely—just within its new verified capacity. This is common when age or wear reduces safety margin.

Conclusion: Reassessment Protects People, Equipment, and Compliance

Your jib crane may be old, but your responsibility to safety is current. Reassessing jib crane load capacity ensures:

- safe lifting performance

- verified structural integrity

- compliant documentation

- reduced downtime from failure

- long-term equipment value

In many workplaces, old cranes continue to serve reliably—but only when their rated performance is confirmed, not assumed.

If you want the strongest safety approach, combine reassessment with ongoing maintenance planning and SWL awareness using these guides:

Please log in to leave a comment.