In any industrial or commercial workspace where material handling is critical, ensuring both safety and efficiency is a top priority. A jib crane is a reliable lifting system often used for precise, repetitive, and confined-space lifting tasks. But while most discussions revolve around the types and uses of jib cranes, an equally important yet under-discussed topic is the importance of jib crane components.

Understanding the role each component plays in your lifting operation can make a significant difference in minimizing hazards, optimizing load handling, and ensuring long-term equipment reliability. In this article, we break down why jib crane components matter in safe lifting systems, and how attention to detail in every part can save costs, prevent accidents, and improve workflow.

Table of Contents

ToggleThe Importance of Individual Jib Crane Components

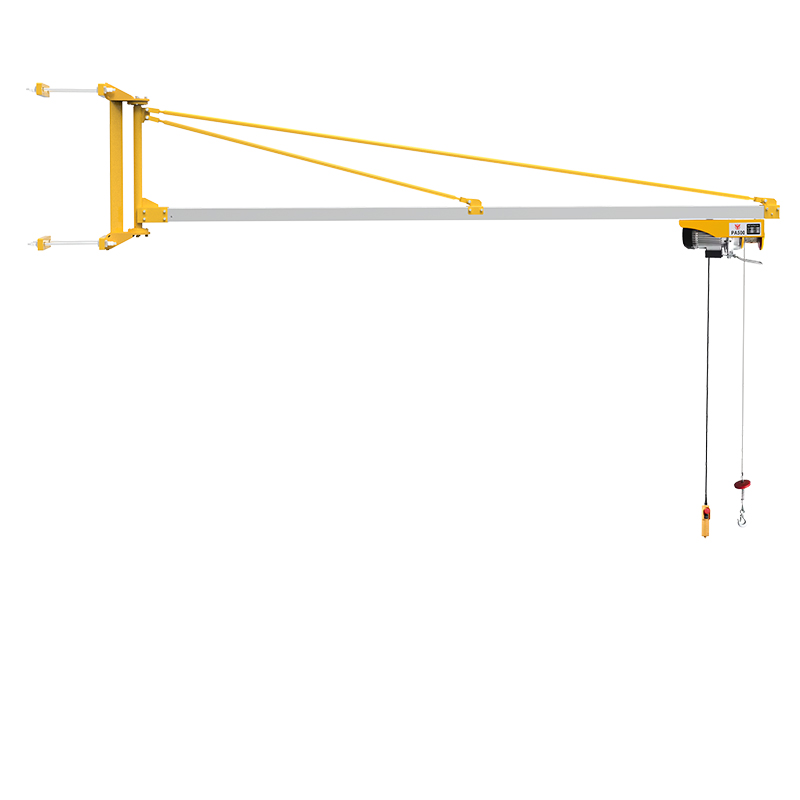

A jib crane system isn’t just a singular machine; it is an assembly of carefully engineered parts working in harmony. Each component supports safety and performance. Here’s a look at the key jib crane components and their critical roles:

1. Base / Mounting System

The foundation of any safe jib crane system lies in its base. Whether it is floor-mounted or wall-mounted, the base ensures structural stability. An improperly secured base can lead to tipping or collapse under load.

Related guide: Small Jib Crane Installation Tips for Narrow Work Zones

2. Mast or Column

This vertical structure supports the boom and enables rotation. The mast must be fabricated from durable steel and firmly connected to the base. Any structural weaknesses can compromise rotational safety.

3. Boom (Swing Arm)

The boom is the horizontal arm that carries the load across the work zone. It’s subject to torsional stress and load distribution, making material strength and build quality essential.

4. Hoist

Arguably the heart of lifting, the hoist raises and lowers the load. Options include manual, electric, or pneumatic hoists. The hoist must match the load requirement and must be routinely inspected for wear and tear.

5. Trolley

The trolley allows horizontal movement along the boom and carries the hoist. A faulty trolley mechanism can derail the entire lifting motion and lead to dangerous load swings.

6. Controls

Whether wired pendant, push-button, or remote, controls must be user-friendly and precise. Overly sensitive or unresponsive controls increase the risk of mishandling heavy loads.

7. Hook and End Effectors

The connection between crane and load, these parts must be robust and suitable for the object being lifted. Custom end effectors may be needed for specific applications.

8. Power Supply & Electrification

Depending on crane type, electrification via festoon systems or conductor bars provides power to the hoist and controls. Proper insulation and cabling are vital for operator safety.

9. Safety Features (Limiters, Alarms, Overload Protection)

Modern jib cranes include built-in safety features that prevent overloads, sudden stops, and motion beyond safe limits. These should never be disabled or ignored.

More insights: Small Jib Crane Safety Features to Prevent Workplace Injuries

How These Components Work Together for Safety

The integrity of the entire jib crane relies on each component performing its role correctly. If any single part fails, the risk of accidents increases exponentially. For example:

- A weak base can destabilize the crane

- A failing trolley may drop or misplace the load

- Inadequate controls can delay emergency stops

Safety is not just about load limits but how the crane reacts under real-world stress, wear, and emergency scenarios.

Preventative Maintenance of Jib Crane Components

Routine inspection and maintenance of each component is essential. Maintenance checklists should include:

- Tightening anchor bolts

- Lubricating trolley tracks

- Checking the wire rope or chain on the hoist

- Testing the emergency stop functions

This proactive care reduces downtime and extends equipment life.

Customization for Operational Demands

Every lifting task is unique. That’s why modularity in jib crane components is important. For instance:

- You can choose between Articulated Jib Crane – Wall Mounted for tight corners

- Swap hooks or use custom lifting clamps for unique materials

- Adapt booms for sensitive loads like a granite countertop

The flexibility of components ensures you always have the right setup.

Improving Workflow with Component Awareness

Understanding your jib crane’s components also boosts productivity. For example:

- Operators know which control speeds work best

- Maintenance teams spot faults faster

- Engineers can upgrade components instead of replacing the whole system

Explore real-world benefits in How Small Jib Crane Improves Workflow in Assembly Lines

Conclusion: Invest in Quality Jib Crane Components

If your goal is to build a safe, efficient, and reliable lifting system, start by understanding your jib crane components. From the foundation to the hook, every part plays a role in lifting safety. Investing in high-quality components and maintaining them properly ensures fewer risks, lower costs, and higher productivity.

For more information, explore our complete line of crane products or reach out to our technical team to customize your solution.

Stay safe. Lift smart.

For more related guide about jib crane components: What Are Jib Crane Components and How Do They Work?

Please log in to leave a comment.