Material handling is an essential part of every industry, from manufacturing and warehousing to construction and logistics. While advanced automated material handling systems are becoming more common, many workplaces still rely heavily on manual material handling tools for everyday tasks. Understanding which devices fall under this category—and how they support workplace safety and productivity—can help businesses make informed choices about their material handling equipment.

Table of Contents

ToggleWhat Is Manual Material Handling Equipment?

Manual material handling (MMH) refers to the use of human power, sometimes assisted by simple tools or devices, to lift, move, push, or carry materials. Unlike automated solutions such as robotic conveyors or automated storage systems, manual handling depends on physical effort with mechanical assistance where necessary.

Some well-known examples include:

- Material handling carts and trolleys – for moving loads across short distances.

- Hand trucks/dollies – simple wheeled devices for boxes, crates, and raw materials.

- Lifting clamps and hooks – used in industries like stone transport.

- Basic hoists – non-powered or manually operated lifting devices.

Examples of Manual Material Handling Equipment

1. Carts and Trolleys

Among the simplest tools, carts and trolleys allow workers to push or pull materials safely. They are commonly used in warehouses and construction sites. For advanced designs, companies often look for the best material handling equipment for warehouses.

2. Hand Trucks and Dollies

These devices reduce strain by leveraging wheels and handles to transport items. They are crucial for logistics and retail.

3. Lifting Clamps

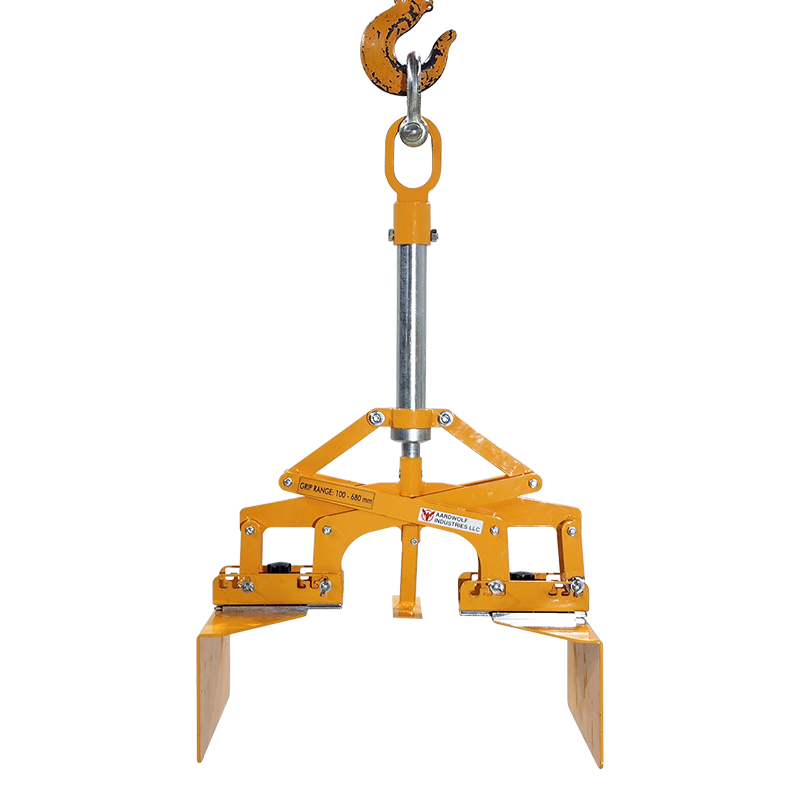

When handling heavy or awkward materials such as slabs or blocks, lifting clamps are indispensable. Products like Aardwolf slab lifters and vacuum lifters enable workers to lift stone, glass, or metal sheets safely.

4. Manual Hoists and Jib Cranes

Though cranes can be powered, smaller versions such as jib cranes or lever hoists are sometimes manually operated for controlled lifting of raw materials.

Manual vs. Automated Material Handling

| Aspect | Manual Material Handling Tools | Automated Material Handling Systems |

|---|---|---|

| Cost | Low initial cost | High upfront investment |

| Flexibility | Adaptable to varied tasks | Optimized for specific workflows |

| Efficiency | Labor-dependent, slower | Faster, consistent, scalable |

| Safety | Requires training and precautions | Reduces human strain and accidents |

Both approaches have their place. In small businesses, low-cost material handling solutions such as trolleys or dollies are often preferred. Larger facilities may integrate conveyors, forklifts, and automated storage systems.

Safety Tips for Manual Material Handling

Manual equipment, while simple, poses risks if misused. Workers should:

- Avoid loose clothing that can get caught in equipment.

- Use proper body mechanics to avoid back injuries.

- Choose the right device for the load size and shape.

- Implement material handling training programs to reduce workplace errors.

Role of Manual Equipment in Different Industries

- Construction – Raw material handling of cement bags, stones, and tiles.

- Warehousing – Movement of boxes, pallets, and packaged goods.

- Food Industry – Small-scale handling of containers and bags.

- Pharmaceuticals – Controlled manual lifting tools for sensitive products.

Integrating Manual Tools With Bulk Systems

While carts, clamps, and hoists are effective, many companies integrate them with bulk material handling systems for large-scale efficiency. This hybrid approach allows businesses to save on costs while benefiting from automation where necessary.

For a complete breakdown, see What Is Bulk Material Handling Equipment?.

Conclusion

So, which is an example of manual material handling equipment? Tools like trolleys, hand trucks, slab lifters, and manual hoists all fall under this category. They remain essential even in highly automated industries because of their affordability, flexibility, and ease of use.

By balancing manual tools with automated systems, companies can build efficient, safe, and cost-effective industrial material handling solutions.

Please log in to leave a comment.