A jib crane is one of the most dependable and versatile lifting systems used in material handling applications across workshops, warehouses, construction sites, and manufacturing plants. But like any mechanical system that operates under repetitive stress, it requires routine and systematic inspection to ensure peak performance and safety.

Inspecting jib crane components properly not only prevents costly downtime but also protects personnel and assets from potential hazards. This detailed inspection guide outlines the crucial steps, procedures, and best practices to evaluate the integrity of each component — from the boom and hoist to controls and power systems.

Before you dive into the details, explore how power systems integrate into crane function: Which Jib Crane Components Require Power or Controls?

Table of Contents

ToggleWhy Jib Crane Inspections Matter

Every lift involves structural load, torsional stress, and friction across several moving parts. Over time, wear and tear on jib crane components can compromise performance and lead to catastrophic failure if ignored. Regular inspections provide multiple benefits:

- Early Fault Detection: Identifies cracks, corrosion, or electrical faults before they escalate.

- Compliance: Meets OSHA and ISO inspection requirements for overhead lifting equipment.

- Operational Reliability: Ensures the crane can perform as intended under rated loads.

- Cost Control: Prevents expensive emergency repairs by catching issues early.

Related: Learn how design improvements boost reliability in How Are Modern Jib Crane Components Designed for Efficiency?

Key Stages of a Jib Crane Inspection

Inspection procedures for jib cranes generally follow three progressive stages: pre-inspection review, visual and functional checks, and load and safety testing.

1. Pre-Inspection Review

Before starting any physical checks, gather essential information and prepare the worksite.

Review Documentation

- Examine the manufacturer’s manual for model-specific inspection guidelines.

- Review previous maintenance logs to identify recurring faults.

- Verify load test certifications and ensure the crane’s operational records are up to date.

Inspect Environment and Setup

- Check surrounding work areas for obstacles or floor irregularities.

- Confirm that the mounting structure (base plate or wall support) shows no signs of stress or corrosion.

- Ensure the rated load signage is visible and legible.

2. Visual Inspection of Structural Components

Visual inspection helps identify physical wear, corrosion, misalignment, and deformation.

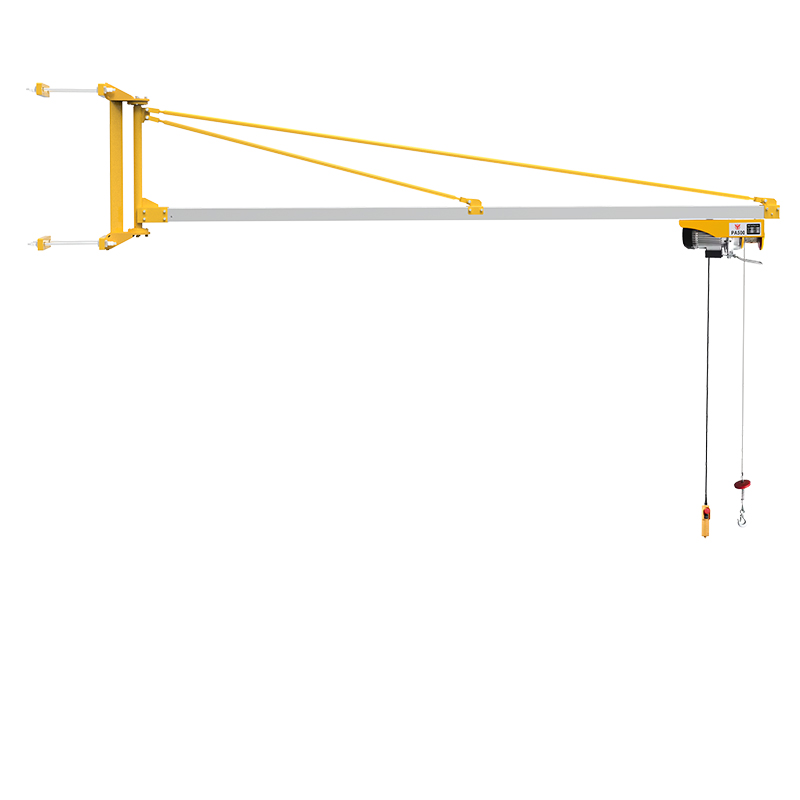

Boom (Jib Arm)

- Inspect for cracks, bends, or weld fatigue, especially near pivot joints and the hoist mounting section.

- Check for paint peeling or rust, which can signal moisture penetration.

- Ensure smooth travel of the trolley across the boom’s full length.

Mast, Pillar, or Wall Bracket

- Confirm that the base bolts are secure and torque-tested.

- For wall-mounted models like the Articulated Jib Crane – Wall Mounted, verify the wall structure and anchor bolts remain free of cracks or deformation.

- Check for vertical plumb alignment to avoid uneven stress.

Slewing or Rotation Mechanism

- Test the rotation manually — it should move smoothly without binding or excessive play.

- Check bearings and gears for signs of lubrication failure or grinding noise.

- Verify that rotation limit stops are properly positioned and functioning.

3. Hoist and Trolley Inspection

The hoist and trolley are critical jib crane components responsible for carrying and positioning the load.

Hoist

- Inspect the chain or wire rope for kinks, fraying, corrosion, or elongation.

- Examine hooks for deformation, cracks, and proper latch operation.

- Verify upper and lower limit switches function correctly.

- Test the brake system for responsiveness and absence of slippage.

Trolley

- Check trolley wheels for flat spots or uneven wear.

- Inspect the track or beam flange for cracks or scoring.

- For motorized trolleys, test travel speed and alignment along the beam.

- Confirm proper lubrication on wheel bearings and gear drives.

4. Power and Control Systems

Any powered crane relies on consistent, safe power distribution and responsive control systems.

Power Supply and Cabling

- Inspect festoon systems, energy chains, or slip rings for cable wear, insulation cracks, or loose connectors.

- Check that electrical junction boxes are sealed and moisture-free.

- Verify correct grounding to prevent electrical hazards.

Control Mechanisms

- Test all pendant controls or radio remotes for directional accuracy.

- Ensure emergency stop (E-stop) functions immediately cut power.

- Examine contactors and relays in the control panel for burns or pitting.

For a deeper understanding of how powered systems function, explore Which Jib Crane Components Require Power or Controls?.

5. Safety Equipment and Limit Devices

Safety mechanisms are the first line of defense against accidents and overload conditions.

Overload Protection

- Calibrate load cells or strain sensors regularly to maintain accurate readings.

- Inspect overload limiters for responsiveness under test loads.

Emergency Systems

- Check alarms, beacons, and cut-off switches for operability.

- Ensure that warning labels remain visible and legible.

Structural Stops and Guards

- Inspect mechanical end stops to ensure they halt travel without excessive shock.

- Confirm that guard panels and shields are secured and not interfering with motion.

6. Functional Testing and Load Verification

After visual and electrical checks, perform operational tests to verify the crane’s performance under working conditions.

No-Load Test

- Operate the crane through its full range of motions: hoist, lower, trolley travel, and slew.

- Observe for unusual noises, vibrations, or sluggish response.

Rated Load Test

- Lift a certified test weight (up to 110% of rated capacity) under controlled conditions.

- Monitor system strain, electrical load draw, and brake holding strength.

- Re-inspect all joints and fasteners after testing for new signs of stress.

7. Documentation and Record Keeping

Proper documentation ensures traceability, compliance, and continuous improvement.

Include the following details in each report:

- Date of inspection and name of inspector

- Serial number and model of the crane

- Condition of key components and any noted defects

- Corrective actions taken or scheduled

- Next inspection due date

Maintain at least the two most recent inspection records on file, as recommended by OSHA. Archiving all historical data is a best practice for performance tracking.

Common Oversights During Inspections

Even experienced teams can miss subtle indicators of component wear. Here are some often-overlooked points:

- Neglecting chain/rope lubrication, leading to accelerated fatigue.

- Ignoring minor anchor bolt loosening, which can evolve into structural failure.

- Skipping electrical insulation testing, increasing fire or shock risks.

- Forgetting control calibration, leading to inaccurate limit stops or unresponsive controls.

Learn what recurring problems to anticipate in What Common Issues Affect Jib Crane Components Over Time?.

Tools and Accessories That Aid in Safer Inspections

During inspection or operation, additional lifting aids from Aardwolf can enhance efficiency and precision:

- Gantry Crane – Perfect for mobile maintenance or testing operations.

- Vacuum lifter – Ideal for checking load stability during lift testing.

- Hoist load testing kits – To verify the accuracy of rated capacity.

- Torque wrenches and ultrasonic thickness gauges – For tightening checks and wall thickness measurements.

These tools ensure inspections are consistent, repeatable, and safe.

Frequency of Jib Crane Inspections

Inspection frequency should match the crane’s duty cycle, environment, and usage intensity:

| Type of Inspection | Frequency | Key Focus |

|---|---|---|

| Initial Inspection | Before first use or after major repair | Verify installation, calibration, and compliance |

| Frequent Inspection | Daily to monthly | Visual and functional checks for wear or damage |

| Periodic Inspection | Every 3–12 months | In-depth review of structure, electrics, and load systems |

High-duty cranes in harsh environments (e.g., foundries or outdoor construction) require more frequent inspections.

The Bottom Line: Inspection Equals Longevity

Properly inspecting jib crane components is a cornerstone of safe and efficient lifting operations. Each inspection ensures the crane performs as designed—stable, precise, and compliant. By creating a structured inspection plan that covers all mechanical, structural, and electrical systems, you extend component lifespan, reduce unplanned downtime, and safeguard your workforce.

For ongoing crane optimization and product options, explore more crane products designed for durability, ergonomics, and productivity.

Please log in to leave a comment.