When a jib crane is installed in a real facility—whether in a fabrication shop, warehouse, stone workshop, shipyard, or manufacturing line—its performance is no longer just a “catalog specification.” Real-world conditions like load cycles, operator habits, structural settlement, corrosion, and maintenance practices can all affect how safely a crane handles load over time. That’s why on-site checks matter. While a full load test and certification is typically performed by qualified inspectors under applicable regulations, day-to-day and periodic on-site checks play a major role in verifying that jib crane load capacity remains consistent, compliant, and safe. The good news is: you don’t need a full engineering lab to detect risks early—you need the right tools and the right process.

This guide breaks down the most practical tools used on-site to check jib crane load capacity, confirm safe working load conditions, support compliance audits, and detect early warning signs before incidents occur.

Table of Contents

ToggleWhy On-Site Tools Matter for Jib Crane Load Capacity

A jib crane that “still lifts” can still be unsafe.

Even if you never intentionally exceed capacity, several things can change over time:

- Load path shifts due to structural wear

- Bolt loosening at foundations or wall brackets

- Hoist brake wear affecting holding performance

- Boom deflection increasing due to fatigue

- Corrosion reducing effective section thickness

- New hoist/trolley upgrades increasing dead load

This is why many facilities combine routine inspection tools with formal certification programs—especially when cranes are older or used heavily.

If you’re managing older equipment, this background article is essential:

👉 Why Old Jib Crane Load Capacity Needs Reassessment?

The 3 Levels of Checking Jib Crane Load Capacity On-Site

Before we list tools, it helps to understand how capacity checking typically happens in real operations:

Level 1: Daily or Weekly Operator Checks

Quick visual and functional checks using basic tools (torque, inspection lights, gauges).

Level 2: Maintenance Team Checks (Monthly/Quarterly)

More detailed checks using measurement and diagnostic tools (deflection, wear, brake performance).

Level 3: Formal Load Testing & Certification (Periodic / After Repairs)

Static + dynamic tests performed by competent persons using calibrated load systems and documented reporting.

This article focuses on tools that support Level 1 and Level 2 checks—and help prepare you for Level 3 certification.

1) Load Measurement Tools (The Most Direct Way to Verify Capacity)

1.1 Load Cells (Inline or Shackled Load Cells)

A load cell is one of the most reliable tools for verifying actual lifted weight during test lifts or critical jobs. It measures the load in real time and displays it digitally.

Why it helps:

- Confirms actual lifted weight (not “estimated” weight)

- Helps prevent accidental overloading

- Creates traceable documentation when paired with logging

- Useful during proof-load testing or troubleshooting

Best use cases:

- Shops lifting variable loads (steel parts, stone bundles, equipment)

- Facilities without consistent load labeling

- Old cranes with uncertain load history

Pro tip: Choose calibrated load cells for serious compliance documentation.

1.2 Dynamometers (Crane Scales)

Dynamometers function similarly to load cells and are often used as a crane scale or tension gauge in lifting systems.

Why it helps:

- Fast weight verification in daily operations

- Provides immediate “yes/no” load confirmation

- Useful for training operators on weight awareness

Limitations:

- Must be used correctly (inline, without side loading)

- Requires periodic calibration to stay accurate

1.3 Built-In Overload Limiters / Load Moment Indicators (LMI)

Many electric hoists can be equipped with overload protection. If your system includes it, test it regularly as part of on-site verification.

Why it helps:

- Prevents operators from exceeding rated capacity

- Reduces risk of structural damage

- Supports compliance documentation

On-site tool approach:

- Verify overload cutoff triggers at correct thresholds

- Check wiring, settings, and response time

- Confirm alarms are audible and visible

2) Tools to Check Structural Integrity (Because Capacity Depends on Structure)

2.1 Measuring Deflection Tools (Laser Distance Meter / Dial Gauge)

One of the biggest warning signs that jib crane load capacity is declining is excessive deflection of the boom under load.

Tools used on-site:

- Laser distance meters (fast, non-contact)

- Dial gauges (high precision)

- Deflection rulers/indicators (simple visual reference)

Why it helps:

- Increased deflection can indicate fatigue or structural weakening

- Helps detect changes from baseline installation condition

- Supports reassessment decisions before major failures occur

Best practice: Record deflection measurements at:

- no load

- typical working load

- near rated load (only under controlled test conditions)

2.2 Crack Detection Tools (Dye Penetrant Kits)

Micro-cracks in welds or joints often appear before failure. Dye penetrant testing is an on-site-friendly method to reveal surface cracks.

Why it helps:

- Detects weld cracking early

- Useful on boom-to-mast joints, bracket plates, base connections

- Affordable and easy for trained maintenance staff

Where cracks matter most:

- Under trolley travel paths

- Mounting bracket areas

- Boom end-stop or rotation stop points

2.3 Ultrasonic Thickness Gauges (Corrosion Assessment)

Corrosion reduces metal thickness—meaning the crane may no longer safely support the original rating.

Why it helps:

- Measures real section thickness through paint/coating

- Detects hidden material loss

- Useful in coastal, chemical, or outdoor environments

This tool is extremely valuable when deciding whether reassessment is required for old cranes.

2.4 Torque Wrench + Bolt Tension Indicators

A crane can be structurally perfect but unsafe if anchor bolts are loose.

Torque tools help verify:

- Base plate anchor bolts (floor-mounted jibs)

- Wall bracket bolts (wall-mounted jibs)

- Slewing bearing bolts

- Hoist mounting fasteners

Why it helps:

- Prevents progressive loosening and sudden instability

- Protects against vibration-related failures

- Creates easy maintenance records

If you want a deeper maintenance-focused approach, read:

👉 What Jib Crane Load Capacity Depends on Proper Maintenance

3) Tools to Verify Hoist & Brake Performance (Capacity Isn’t Only Structure)

Even when the structure is strong, the hoist system can fail under load if braking is weak, controls malfunction, or lifting media is worn.

3.1 Brake Performance Test Tools

A key part of verifying jib crane load capacity is ensuring the brake can hold the load safely.

On-site methods include:

- controlled brake holding checks

- timed “hold” tests

- inspection tools for brake wear measurement

- torque measurement tools on braking assemblies

What you’re looking for:

- drift or creep under suspended load

- delayed stopping

- overheating or smell

- inconsistent holding force

3.2 Wire Rope / Chain Inspection Tools

Your crane might be rated for 2 tons, but if the chain or rope is compromised, the safe working load is effectively lower.

Helpful tools:

- chain wear gauges

- rope diameter gauges

- magnifying inspection lens

- calipers for hook throat opening

Check these frequently:

- broken strands

- corrosion pitting

- kinks, bird-caging

- hook deformation

- worn chain links

3.3 Electrical & Control Diagnostics (Multimeter, Contact Tester)

Electrical issues can lead to unsafe behavior: delayed stops, uncontrolled movement, or faulty overload protection.

Why it matters to capacity:

Capacity is safe only when the crane is controllable. Erratic controls can increase dynamic shock loading (which increases stress beyond static load weight).

Tools used on-site:

- multimeter

- insulation resistance tester

- contact tester for switches

- pendant / remote control testing tools

4) Proof Load Testing Tools (Used During Formal On-Site Testing)

On-site checks often lead to one question: Should we schedule a load test?

A professional crane load test typically includes:

- Static load test (commonly 125% of rated capacity)

- Dynamic load test (commonly around 110% of rated capacity)

To achieve this, inspectors use controlled testing equipment.

4.1 Calibrated Test Weights

These are solid weights with known mass, used to validate structural response.

4.2 Water Bags (Proof Load Water Bags)

Water bags are commonly used because:

- easy transport

- adjustable fill level

- safe, controlled load application

4.3 Hydraulic Test Systems

Hydraulic load test systems can simulate load without moving heavy weights, but are typically specialist tools.

Why these matter:

They support certification and compliance by proving the crane can safely lift and hold beyond rated conditions—under controlled procedures.

5) Documentation Tools (Because On-Site Checks Must Be Traceable)

If your facility is serious about compliance and safety, the tools aren’t just physical—they include systems for proof.

5.1 Digital Inspection Checklists (Mobile Apps / Tablets)

Modern facilities use inspection apps or digital forms that:

- standardize inspections

- reduce missed items

- store photos and records

- generate audit-ready reports

5.2 Tagging and Load Rating Labels

On-site, the simplest compliance tool is a clear label:

- SWL / WLL marking

- test date

- next inspection due date

- serial number and model ID

These markings ensure operators always know safe limits.

This links closely to SWL understanding:

👉 How Jib Crane Load Capacity Relates to Safe Working Load

6) The Most Overlooked Tool: A Capacity Checklist for Operators

Even with sensors and gauges, operators remain the first line of safety.

A good on-site capacity checklist includes:

✅ Verify load weight (load cell or documented weight)

✅ Confirm rigging is rated above the load

✅ Ensure load is centered under hook

✅ Avoid side pulling

✅ Confirm crane path is clear

✅ Check for abnormal noise, vibration, or deflection

✅ Ensure overload limiter is active (if equipped)

✅ Stop immediately if capacity is uncertain

If you’re unsure what happens when capacity is exceeded, this is critical reading:

👉 What If Jib Crane Load Capacity Is Exceeded

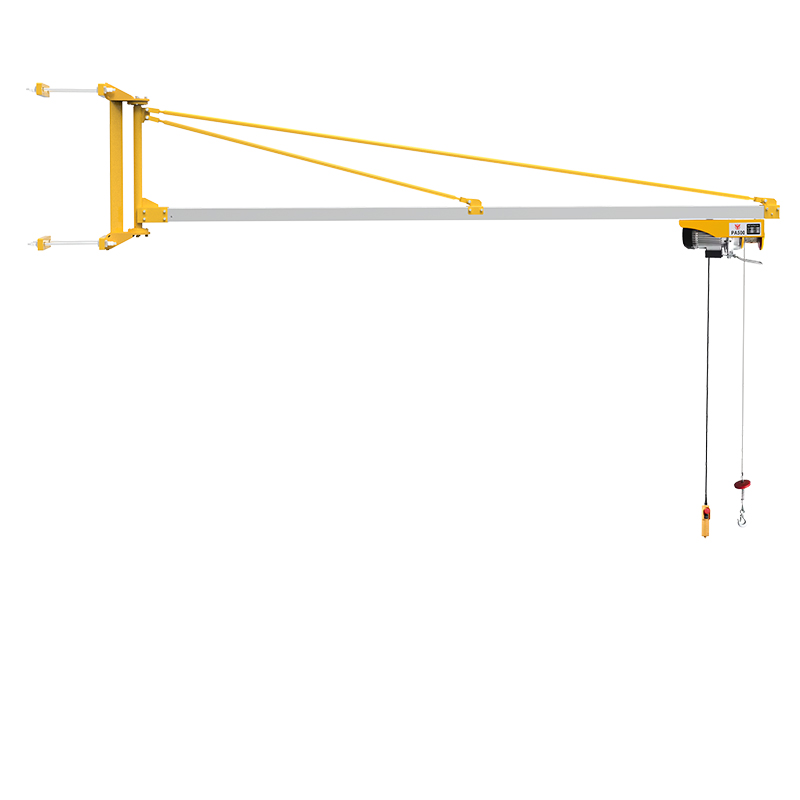

Recommended Jib Crane Options for Better On-Site Capacity Control

If your site demands high maneuverability with precise movement around obstacles, an articulated jib is often a strong choice:

👉 Articulated Jib Crane – Wall Mounted

And if you want to compare more models by capacity and configuration:

FAQ: Tools to Check Jib Crane Load Capacity On-Site

What is the best tool to measure lifted weight on a jib crane?

A calibrated load cell or dynamometer is the most direct and accurate on-site tool.

Can I verify jib crane load capacity without load testing?

You can verify condition and detect warning signs, but only formal testing confirms performance under proof loads for certification.

How do I know if my jib crane’s capacity has changed over time?

Watch for changes in deflection, noise, brake holding behavior, corrosion, cracks, and bolt loosening—then schedule reassessment and testing if needed.

How often should on-site checks be done?

- Operator checks: daily/weekly

- Maintenance checks: monthly/quarterly

- Formal load testing: after installation, relocation, repairs, and periodically depending on regulation and usage

Conclusion: The Right Tools Protect Capacity, People, and Compliance

Checking jib crane load capacity on-site isn’t just about preventing overload—it’s about building confidence in your lifting system every day. With the right tools—load cells, deflection measurement, crack detection, torque verification, hoist diagnostics, and strong documentation—you can detect early risk factors long before they become dangerous failures.

Most importantly, on-site checks help you decide when reassessment or formal testing is necessary—especially for older cranes or high-cycle operations.

Use these supporting guides to strengthen your internal safety system:

Please log in to leave a comment.