Maintaining a crane isn’t just about keeping it running—it’s about preserving rated performance and ensuring the crane can safely lift what it’s designed to lift every single day. For factories, workshops, warehouses, and heavy industrial facilities, jib crane load capacity is not a “set-and-forget” number. Over time, mechanical wear, improper lubrication, structural fatigue, and neglected inspections can slowly reduce lifting reliability and compromise safety.

That’s why the most successful crane operators focus on proactive maintenance. A consistent maintenance program protects your jib crane’s capacity by ensuring the crane remains aligned with its rated limits, Safe Working Load (SWL/WLL), and compliance requirements—while minimizing downtime and repair costs.

In this guide, we’ll explain what maintenance activities directly preserve jib crane load capacity, how to detect early warning signs, and what inspection schedule helps keep your crane safe and dependable long term.

Table of Contents

ToggleWhy Jib Crane Load Capacity Depends on Maintenance

When you install a jib crane, its rated capacity is established based on engineering design, tested structural strength, and equipment configuration. But the crane’s real-world performance depends on how well it’s maintained.

Here’s what can happen without maintenance:

- Bearings wear and rotation becomes uneven

- Hoists develop brake slippage and lifting becomes unstable

- Bolts loosen and alignment shifts

- Wire ropes or chains degrade and reduce lift safety

- Corrosion reduces structural integrity

- Limit switches fail and increase overload risk

The result is simple: capacity becomes unreliable, and your risk of accidents rises sharply. In the worst cases, poor maintenance leads to overload incidents or structural failure—especially if operators unknowingly push the crane near its limit.

If you want to understand the outcomes and dangers of lifting beyond rated limits, read:

👉 What If Jib Crane Load Capacity Is Exceeded

What “Consistent Jib Crane Load Capacity” Really Means

To maintain consistent jib crane load capacity, you’re not trying to “increase capacity.” You’re trying to ensure the crane can:

✅ Lift within rated load without excessive strain

✅ Maintain smooth rotation and trolley movement under load

✅ Keep deflection within acceptable limits

✅ Protect structural integrity over years of repetitive lifting

✅ Meet inspection and compliance standards

✅ Prevent overload and dynamic impact damage

That consistency requires targeted maintenance—especially on load-bearing parts.

The 7 Maintenance Areas That Protect Jib Crane Load Capacity

Below are the key maintenance categories that directly affect crane performance and lifting safety.

1) Lubrication of Rotation Bearings and Slewing Mechanisms

If your jib crane rotates stiffly or unevenly, load handling becomes less stable, increasing dynamic forces. Over time, poor rotation can cause lateral stress and faster fatigue.

Lubrication checklist:

- Slewing bearings / pivot points

- Rotation gear teeth (if geared rotation)

- Bushings and pins on articulated systems

- Thrust bearings on mast/freestanding cranes

Why it preserves capacity:

Smooth rotation prevents shock loading and unintended side forces that can gradually weaken structure.

2) Structural Inspections: Mast, Boom, Brackets, and Welds

Your crane’s structure is the foundation of its rated capacity. Even minor cracks, corrosion, or bolt loosening can turn a rated system into a risk zone.

Inspect for:

- Boom deflection beyond normal

- Hairline cracks at welds

- Corrosion on the boom or column

- Deformation in wall brackets

- Base plate movement (floor-mounted cranes)

- Anchor bolt elongation or looseness

Why it preserves capacity:

Structural fatigue is cumulative. Early detection prevents permanent deformation, which compromises load rating.

3) Hoist Maintenance (Brakes, Motor, Gears)

The hoist is often the first component to show overload damage. A poorly maintained hoist may still lift a load—but without safe control.

Routine checks should include:

- Brake function and brake wear

- Gearbox oil condition

- Motor overheating signs

- Hoist limit switches

- Hook latch and hook throat opening

- Load chain or wire rope wear

Why it preserves capacity:

Your jib crane load capacity is meaningless if the hoist cannot safely lift and hold the load. Hoist failure is one of the most common causes of load drops and overload incidents.

4) Wire Rope, Chain, and Hook Condition Checks

Even if your crane structure is perfect, worn lifting media reduces safety instantly.

Check for:

- Fraying, kinking, birdcaging (wire rope)

- Chain stretch, corrosion, cracks

- Hook deformation or twisting

- Hook latch failure

- Excessive wear on sheaves

Why it preserves capacity:

A crane might be rated for 2 tons, but if the rope or chain is compromised, the safe working load becomes much lower in practice.

5) Trolley and Track Maintenance (Travel Performance Under Load)

The trolley carries load and moves along the boom. Poor trolley performance adds load swing, shock, and uneven distribution—all of which reduce effective capacity control.

Inspect and maintain:

- Trolley wheels wear and alignment

- Track surface condition

- End stops and bumpers

- Trolley motor (if motorized)

- Fasteners and wheel bearings

Why it preserves capacity:

Smooth travel keeps loads stable. Jerky travel increases dynamic loads and side pulling—both harmful to structure and hoist.

6) Electrical and Control System Checks

Control failures can cause:

- sudden starts/stops

- uncontrolled travel

- limit switch failure

- overload protection malfunction

Maintenance includes:

- verifying pendant and remote controls

- checking wiring connections and cable festoons

- confirming emergency stop function

- testing overload limiter functionality

- inspecting contactors, relays, and breakers

Why it preserves capacity:

If the crane behaves unpredictably, operators compensate manually—often causing side loading or unsafe lift motions.

7) Load Testing and Verification (Periodic)

Routine inspections catch wear, but periodic testing verifies capacity and performance.

Typical load testing includes:

- rated load lift tests

- functional movement tests under load

- brake hold tests

- rotation smoothness checks

- limit switch and overload device tests

Why it preserves capacity:

Testing confirms that your crane can safely operate at its rated capacity—not just “move,” but lift and control loads correctly.

The Maintenance Schedule That Best Preserves Jib Crane Load Capacity

Here’s a practical schedule used across many industrial operations:

Daily (Operator Pre-Use Checks)

- hook + latch condition

- unusual noises

- control function test

- chain/rope visible wear

- rotation and trolley movement check

- verify capacity signage is visible

Weekly

- lubrication (light-duty depending on usage)

- inspect hoist chain/rope more thoroughly

- check pendant wiring and cable wear

- verify bolts are visually secure

Monthly

- detailed inspection of bolts, base plate, wall brackets

- check hoist brake performance

- inspect bearings and wheel wear

- check limit switches and stops

Quarterly / Semi-Annual

- structural inspection for cracks and corrosion

- trolley alignment and track wear check

- inspect electrical components

- confirm anchoring integrity

Annual

- professional inspection (or certified third-party, depending on local regulations)

- full load test or capacity verification

- documentation review for compliance

Why Maintenance Is Also a Compliance Requirement

Many businesses treat maintenance as a cost. But for lifting equipment, it’s a compliance safeguard. Regulators care about:

- proof of routine inspection

- documented repairs and part replacements

- adherence to rated capacity limits

- training records

- test certificates

If your crane is involved in an incident, your documentation will be reviewed immediately.

To understand why capacity and documentation are linked to compliance, read:

👉 Why Jib Crane Load Capacity Is Crucial for Compliance

How Maintenance Supports Safe Working Load (SWL/WLL)

Safe Working Load is the practical operational limit used in real environments—and it depends heavily on condition.

A crane may be rated for 2 tons, but if:

- the hoist brake is worn

- the chain is stretched

- the boom has deflection

- the trolley is misaligned

…then safe lifting becomes uncertain. That’s why SWL and load capacity are tightly tied to inspection and testing.

For deeper understanding, see:

👉 How Jib Crane Load Capacity Relates to Safe Working Load

Common Maintenance Mistakes That Reduce Load Capacity Reliability

Even high-quality cranes lose performance when teams make these mistakes:

❌ Ignoring early warning signs

- squealing bearings

- inconsistent rotation

- hoist slowing under load

- frequent overload alarms

- increased load swing

❌ Skipping lubrication

Dry bearings cause wear that permanently affects rotation performance.

❌ Overloading “just once”

A single overload event can deform structure or damage hoist components.

❌ Using incompatible hoist/trolley combinations

Improper components shift load distribution and risk exceeding safe design limits.

❌ Poor operator training

Untrained operators often side pull loads, shock load, or move too fast—creating dynamic forces beyond safe limits.

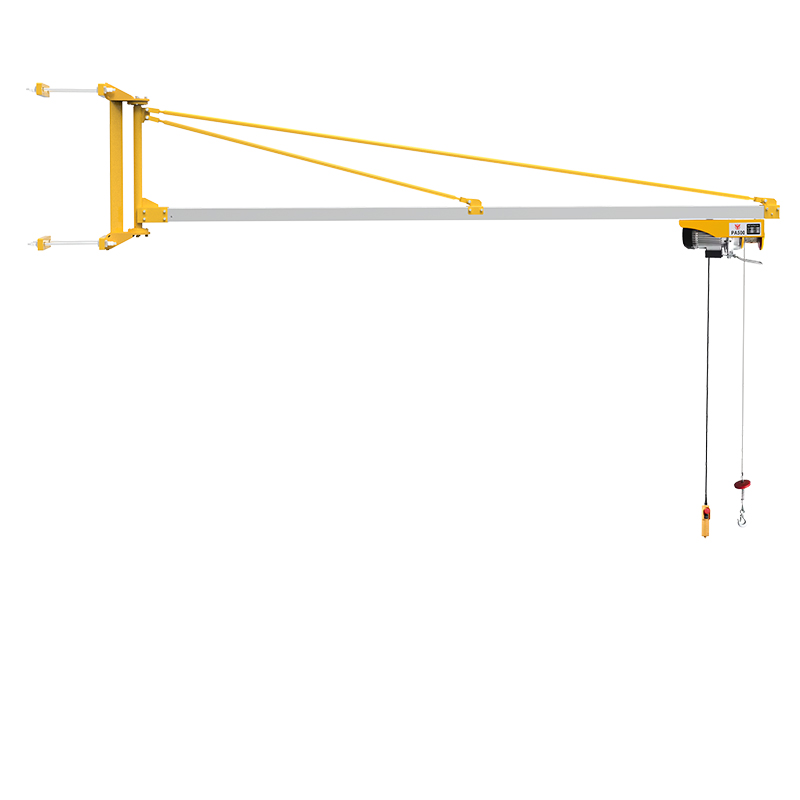

Why Wall-Mounted and Articulated Jib Cranes Require Special Attention

Wall-mounted cranes depend on building structure. So maintenance must include:

- bracket and wall anchor inspections

- structure assessment (especially after facility modifications)

- crack checks around mount points

Articulated cranes add moving joints, so maintenance must also cover:

- joint lubrication and bushing wear

- arm alignment

- rotation smoothness on inner and outer arms

If you’re using an articulated wall-mounted system, you can explore a suitable model here:

👉 Articulated Jib Crane – Wall Mounted

Practical Tip: Maintenance Should Match Duty Cycle

A jib crane used 10 lifts/day needs a different maintenance intensity than one used 200 lifts/day.

If your operation involves:

- repetitive production lifting

- heavy loads near maximum capacity

- frequent rotation and trolley travel

Then you should:

✅ increase lubrication frequency

✅ shorten inspection intervals

✅ schedule quarterly verification

✅ maintain spare parts for hoist wear items

Need the Right Crane for Long-Term Reliability?

Maintenance works best when your crane is matched to the job.

If you’re selecting or upgrading your system, browse:

👉 more crane products

Conclusion: Maintenance Is What Protects Jib Crane Load Capacity Over Time

Your jib crane load capacity is only dependable when your crane remains in verified, safe condition. That means:

✅ routine inspections

✅ lubrication of bearings and rotation points

✅ hoist and rope/chain checks

✅ structural inspection and corrosion prevention

✅ electrical control verification

✅ periodic load testing and documentation

When these practices are followed, your crane delivers long-term performance, fewer breakdowns, safer lifting, and stronger compliance readiness—year after year.

Please log in to leave a comment.