Exceeding jib crane load capacity isn’t just “pushing it a little.” It’s a cascade of mechanical, structural, legal, and financial consequences that can jeopardize people, damage equipment, and shut down production. This guide explains exactly what happens when a jib crane is overloaded, how to recognize the warning signs, what to do if it occurs, and—most importantly—how to prevent it with practical, audit-ready controls.

Table of Contents

ToggleQuick refresher: what “capacity” really includes

When we talk about jib crane load capacity, we’re talking about more than the nameplate tonnage.

- Rated load (capacity): The maximum safe load the crane can lift under normal conditions.

- System capacity: Jib structure plus foundation or wall/column supports plus hoist/trolley plus anchors plus below-the-hook (BTH) devices and rigging.

- Capacity at radius: With a jib (a cantilever), usable capacity depends on load radius (distance from the column/pivot). The further out you lift, the lower the effective capacity can become.

Want to see how engineers standardize sensible choices across duty classes and radii? Read: What Jib Crane Load Capacity Engineers Commonly Choose

What actually happens when capacity is exceeded

1) Structural overstress and permanent deformation

- Boom/jib deflection increases sharply near the tip. Exceeding yield strength can cause permanent set (the boom never returns true), locking in misalignment and reducing future capacity.

- Mast/column bending and localized yielding around baseplates or wall brackets can elongate bolt holes and loosen fasteners—damage that’s often invisible until the next heavy pick.

2) Anchor and foundation failure (freestanding) or column failure (wall-mounted)

- Overload increases overturning moment. On freestanding jibs, that can pull anchors, crack grout, or spall concrete.

- On wall-mounted jibs, excessive moment can crush masonry, buckle a weak column flange, or shear anchors—especially if the supporting structure wasn’t verified for the full load at radius.

Choosing wall-mounted models? See how capacity and building checks go hand-in-hand:

Which Jib Crane Load Capacity Suits Wall-Mounted Models?

3) Hoist, trolley, and drive damage

- Hoist brakes may slip; gearboxes overheat; wire ropes/chains suffer accelerated wear or shock loading.

- Trolley wheels can flat-spot or derail if side-loading occurs due to large deflections and load swing.

4) Uncontrolled load behaviour

- Excess flex and brake slippage produce load swing, pendulum effects, and side pull, which are specifically prohibited practices and dramatically increase risk to personnel.

5) Immediate safety and legal exposure

- Overloading is a bright-line compliance breach and a reportable near-miss or incident in many jurisdictions. Expect investigations, corrective-action demands, and potential fines.

For the compliance context and what auditors look for, bookmark:

Why Jib Crane Load Capacity Is Crucial for Compliance

Hidden costs you’ll feel long after the incident

- Chronic misalignment → more side pull → faster rope/chain wear → more downtime.

- Insurance implications: non-compliant use can void coverage or increase premiums.

- Product damage: tilting, sudden set-downs, or dropped loads.

- Productivity loss: rework, inspections, retraining, and temporary derating of the crane.

Why overload happens (even to careful teams)

- Rigging mass and geometry ignored.

BTH devices (clamps, spreaders, magnets), slings, and shackles add dead weight. Sling angle can multiply line tension well beyond the hook load. - Capacity-at-radius overlooked.

Operators lift “at the tip” because it’s convenient. If selection or signage doesn’t reflect radius limits, overload is easy. - Duty and dynamics underestimated.

High cycle counts, inching, or fast slewing introduce shock loading. The effective load isn’t just the static weight. - Support structure never verified.

Wall/column strength or freestanding foundations weren’t engineered for real-world use at the dominant radius. - Application variability.

Different industries and cells see different load families, environments, and duty cycles—hence different safe capacities. Compare use cases here:

Why Jib Crane Load Capacity Varies Across Applications

Early warning signs of overloading

- Unusual deflection of the boom or “springy” feel during lift.

- Creaks/grinding from mast base, wall bracket, or anchors.

- Hoist brake slip or load lowering when controls are neutral.

- Increased swing and difficulty keeping the hook plumb.

- Triggered overload protection or tripped limiters.

- New cracks in grout, floor, wall, or column connections.

If any of these appear, stop, secure the area, and escalate.

What to do immediately after an overload (or suspected overload)

- E-stop and tag out. Secure the load safely (jack/support if needed).

- Clear and barricade the zone. No one under/near the load path.

- Incident capture. Record load details (weight, radius, rigging list), who, where, when. Photos help.

- Qualified inspection.

- Visual: boom, mast/column, brackets, anchors, welds, trolley track.

- Functional: brake hold test, limit switches, trolley/rotation.

- Structural: measure deflection under known test load; check fastener torque; NDT critical welds if deformation suspected.

- Engineering review. PE or manufacturer reviews any deformation, anchor distress, or foundation damage and prescribes repair or replacement.

- Recommissioning test. Proof load at prescribed percentage and radius, with results logged.

- Root cause + retraining. Update lift plans, capacity signage, and SOPs.

Preventing overload: a practical, audit-ready playbook

1) Calculate “effective pick” weight, not just part weight

Effective pick = (Load) + (BTH + rigging mass) × (application factor)

- BTH + rigging: include spreader bars, clamps, magnets, slings, shackles.

- Application factor (typ. 1.10–1.25): accounts for dynamics, hoist/trolley mass, and handling style.

Example: 1,450 kg part + 110 kg of spreader, slings, shackles = 1,560 kg.

With 1.2 factor → 1,872 kg effective. Select and post for this.

2) Post capacity at radius

Replace generic tonnage placards with a simple capacity vs. radius chart at the pendant. If 80–90% of picks are near the tip, either upsize the crane or derate and document.

3) Engineer the support

- Wall-mounted: verify column/wall section, connection design, and anchors for full moment at intended radius.

- Freestanding: match foundation and anchor pattern to manufacturer’s spec (or better). Preserve the torque log.

When obstacles force awkward approaches, an articulated arm keeps lifts vertical and compliant:

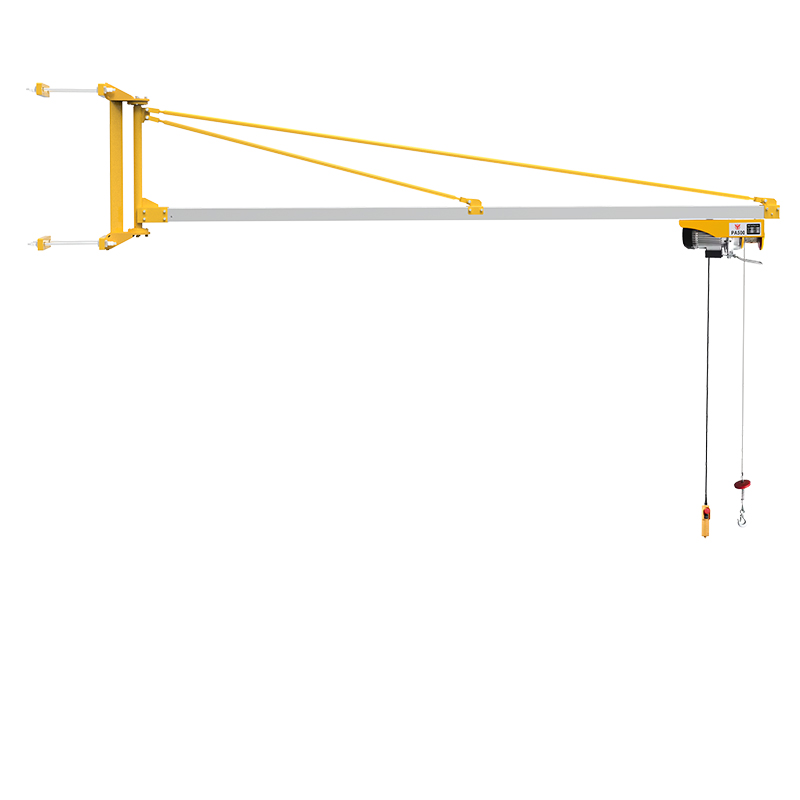

Articulated Jib Crane – Wall Mounted

4) Standardize rigging and keep WLL visible

- Maintain a rigging register (weights and WLL).

- Use angle charts at the rigging station.

- Pre-lift checklist: WLL tags present, sling angles acceptable, clamp engagement verified.

5) Train to your exact setup

General crane training is not enough. Operators need site-specific instruction on your capacity-at-radius chart, typical rigging loads, and emergency steps. Reinforce with short toolbox talks after any process or product change.

6) Inspect and trend

- Daily/shift checks by operators (hook, chain/rope, brakes, deflection cues).

- Frequent/periodic inspections by a qualified person, with findings tracked to closure. Trend brake slippage, anchor retorque needs, and deflection measurements.

Selecting capacity to avoid overload in the first place

- Match to the heaviest routine lift, not the rare outlier—but include the effective pick and radius where you actually work.

- Use duty class that fits your starts/hour and expected service life.

- In tight cells or around fixtures, consider articulated jibs to minimize side pull and keep radius conservative.

- If your product mix is evolving, build a capacity matrix by workstation or product family and review quarterly.

Exploring options or planning an upgrade? Browse more crane products to align capacity, radius, and duty class with your environment.

FAQs

Is a brief overload acceptable if nothing “broke”?

No. Even a single overload can leave hidden damage (micro-cracks, bolt stretch, foundation spalls) that reduces future safety margin. Treat as an incident: inspect, engineer, and re-test.

Can I compensate by lifting slower?

Slower helps with dynamics but does not increase structural capacity. The only compliant fixes are derating, re-engineering, or selecting a higher-capacity system.

What about frequent light loads at long radius?

Capacity at radius still governs. If most picks are at the tip, choose a crane sized for that outreach—or shorten the working radius with fixtures/stops.

The real takeaway

Exceeding jib crane load capacity sets off a chain of risks: deformation, anchor/column distress, hoist damage, uncontrolled load motion, and regulatory exposure. The solution is not guesswork; it’s a repeatable method:

- Calculate effective pick (load + rigging) with a sensible application factor.

- Verify and post capacity by radius.

- Engineer and document the supporting structure.

- Standardize rigging and training.

- Inspect, trend, and improve.

Do that well and overload becomes both unlikely and easily detectable—keeping people safe, uptime high, and audits calm.

Please log in to leave a comment.