Your Expert Guide to Equipment, Types, Benefits & Best Practices

Material handling sits at the core of logistics, construction, warehousing, and manufacturing. The right equipment not only keeps goods flowing smoothly but also slashes labor costs, reduces risk, and enables organizations to meet today’s high standards for efficiency and safety. But what exactly are material handling equipment, and which ones matter most for your operation?

This in-depth guide explores the major categories, real-world benefits, key functions, and expert advice for optimizing your material handling system.

Table of Contents

ToggleWhat Is Material Handling Equipment?

Material handling equipment includes any tools, machines, vehicles, or systems designed to move, store, protect, or control materials through every stage of production, distribution, storage, or disposal. These solutions range from simple wheelbarrows, pallets, carts and manual devices to highly automated robots, conveyors, and cranes.

Want to start with the basics? Explore What Is Material Handling?

Main Categories of Material Handling Equipment

- Transport Equipment

Equipment that moves materials from one location to another within a facility or job site.- Examples: Forklifts for construction, pallet jacks, hand trucks, carts, AGVs (automated guided vehicles)

- Learn more: Forklifts, Pallet Jacks, and Dollies Are Examples of What Material Handling Equipment?

- Storage and Handling Equipment

Solutions to efficiently store, organize, and protect goods.- Examples: Racks, shelves, bins, automated storage and retrieval systems (AS/RS)

- Purpose: Maximizes space and inventory visibility

- Unit Load Formation Equipment

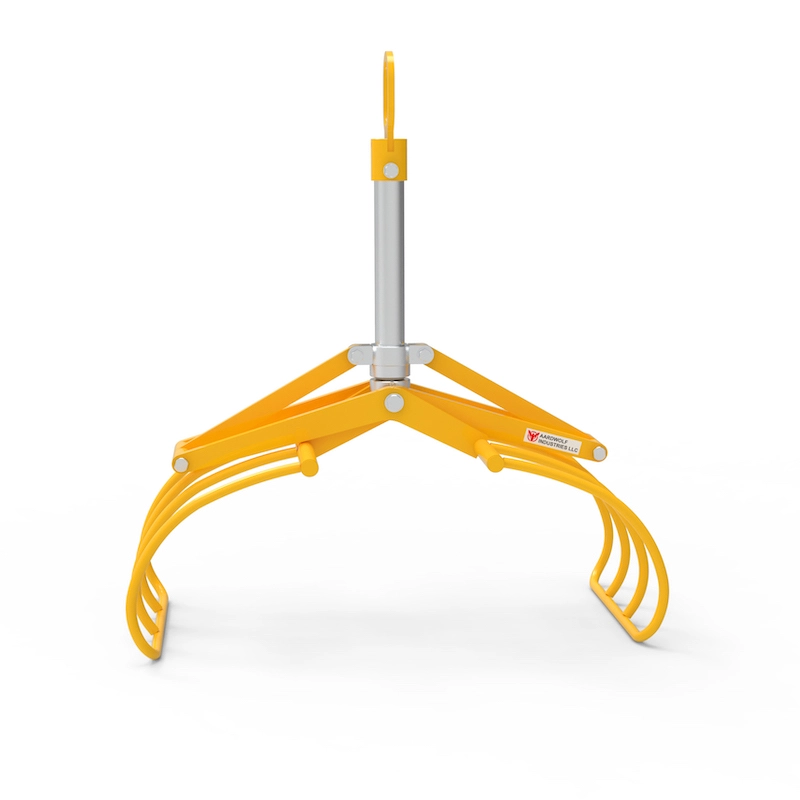

Devices that consolidate individual items into unit loads for easy transport and storage.- Examples: Pallets, containers, slip sheets, and Aardwolf Slab Lifters for slabs and large panels

- Lifting and Positioning Equipment

Tools and machines that raise, lower, or position materials for handling, processing, or assembly.- Examples: Jib Cranes, hoists, scissor lifts, Vacuum Lifters

- More info: Material handling Equipment

- Conveying Equipment

Automated or semi-automated systems for continuous movement of materials across distances or between processes.- Examples: Conveyor belts, roller conveyors, overhead conveyors, pneumatic conveyors

- Used in: Warehouses, assembly lines, and construction site logistics

Why Is Material Handling Equipment So Important?

Proper material handling is fundamental for:

- Reducing Labor Cost in Construction & Warehousing: Automated and ergonomic equipment allows fewer people to do more with less effort.

- Improving Safety: The right equipment—like hoists, Vacuum Lifters, and Jib Cranes—reduces lifting injuries and accidents.

- Increasing Construction Productivity: Efficient flow and access to materials keep projects on schedule and reduce downtime.

- Minimizing Material Waste: Gentle, precise handling means fewer dropped, damaged, or lost items.

- Optimizing Warehouse Space: Proper storage and movement equipment ensure every square meter is used efficiently.

See real-world benefits at What Is Material Handling Equipment?

How to Choose the Right Material Handling Equipment

Selecting the right solution depends on:

- The types, shapes, and weights of materials handled

- Volumes and throughput requirements

- Space and layout of your facility or job site

- Safety and compliance standards

- Budget and return on investment

For expert guidance, review Material-handling Equipment.

Material Handling Equipment in Practice: Construction and Warehousing

Construction

On job sites, lifting heavy slabs, steel, and precast concrete requires rugged, specialized equipment. Aardwolf Slab Lifters, forklifts, and Jib Cranes reduce labor, boost safety, and speed up installation.

Warehouse and Distribution

In a modern warehouse, forklifts, conveyor systems, and Vacuum Lifters enable fast, efficient movement, storage, and picking. Material storage solutions and smart layouts further enhance productivity and minimize waste.

For more examples and strategies, see What Is Material Handling in Warehouse? and What Is Material Handling?.

Manual vs. Motorized vs. Automated Equipment

- Manual: Hand trucks, carts, and dollies—simple, flexible, and cost-effective for low volumes.

- Motorized: Forklifts for construction, powered conveyors, and hoists for higher capacity and throughput.

- Automated: Robotics, Vacuum Lifters, and AGVs for large, complex, or high-speed environments.

Understand the full range and benefits at What Is Material Handling?.

Best Practices for Safe and Efficient Material Handling

- Train your team in proper use of equipment and safety standards.

- Maintain equipment with regular inspections and servicing.

- Design smart layouts for clear traffic flow, storage, and access.

- Integrate technology such as warehouse management systems (WMS) for real-time control.

- Match equipment to your materials and operational requirements.

Conclusion

Material handling equipment is the engine of modern business operations, enabling the safe, efficient, and cost-effective movement of goods. By investing in the right mix—from Aardwolf Slab Lifters to Vacuum Lifters, Jib Cranes, conveyors, and pallets—you’ll minimize waste, reduce labor costs, improve safety, and unlock higher productivity.

For tailored solutions and the latest innovations, consult with trusted suppliers and certified material handling experts.

Related reading:

Please log in to leave a comment.