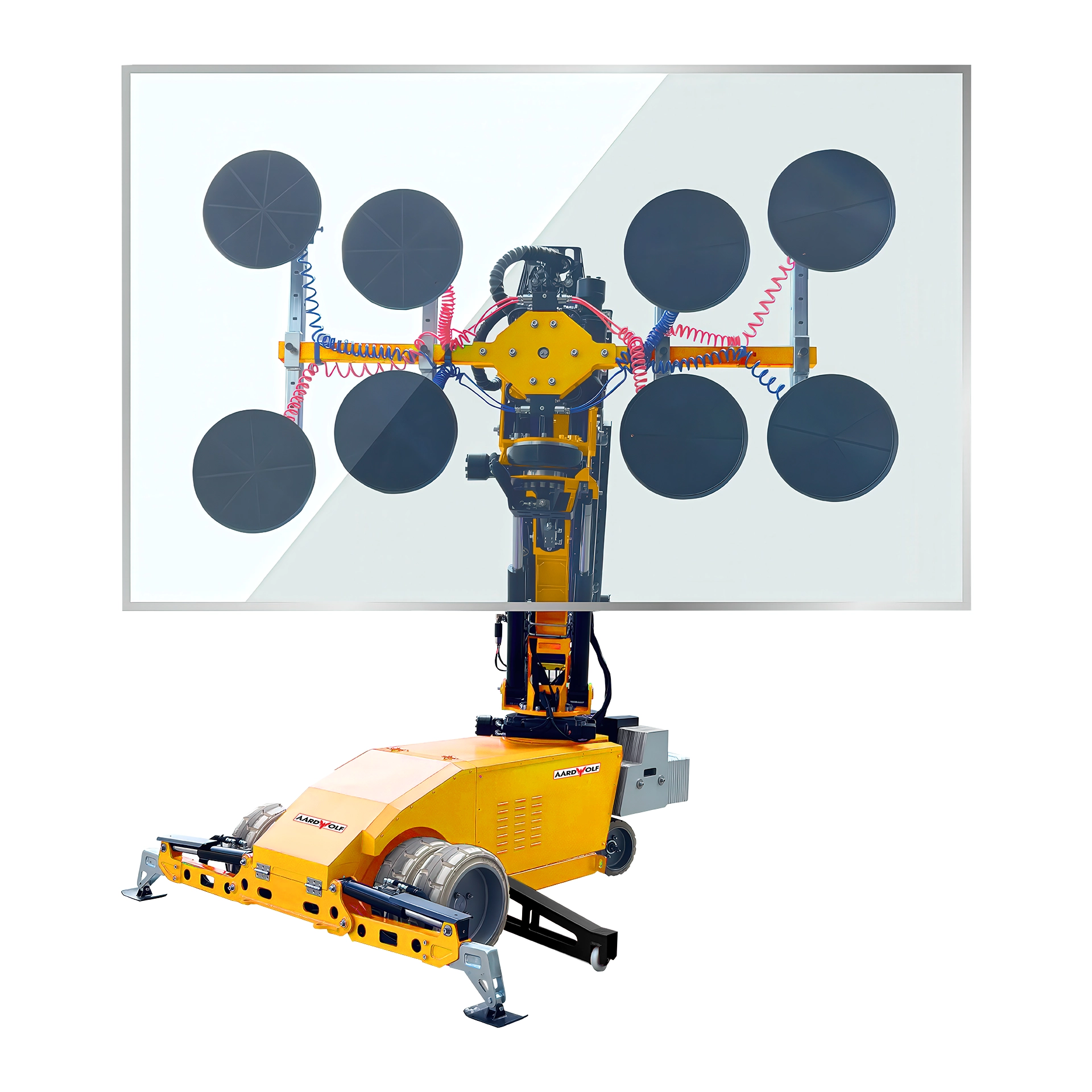

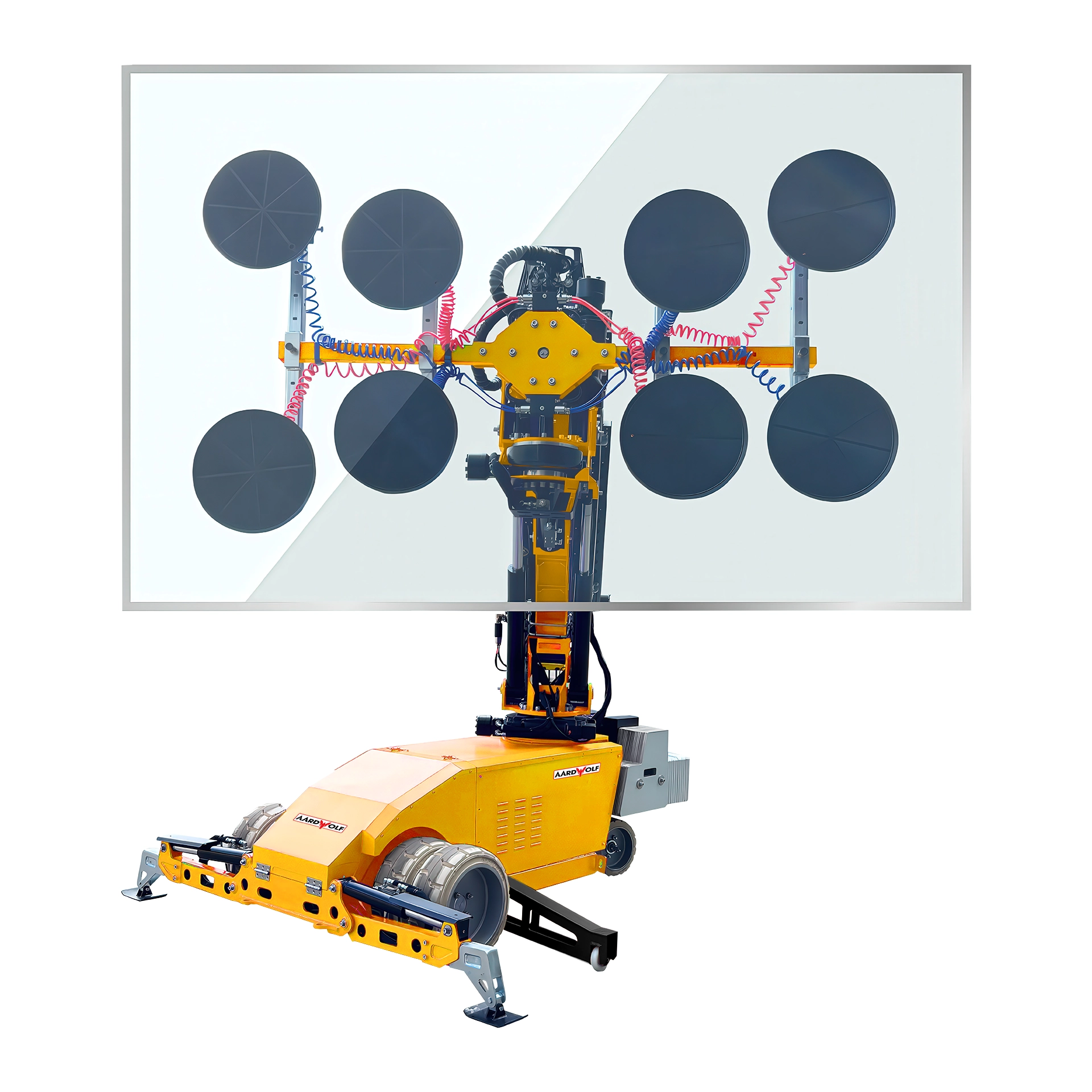

Introduction – Aardwolf Glazing Robots

The AGR-1000 is a high-capacity glass robot from Aardwolf Glazing Robots, engineered for installing large, heavy panels on high-rise façades and industrial projects. With a robust vacuum suction system and precision controls for lifting, extending, rotating, tilting, and moving glass, it reduces manual labor, enhances site safety, and improves installation accuracy. Interchangeable tool heads (e.g., forks, winches, suction) let the AGR-1000 adapt to diverse tasks on demanding jobsites.

General Features – Aardwolf Glazing Robots

-

Vacuum suction system enabling rotation, tilting, and controlled glass movement.

-

Wireless remote control with speed adjustment for precise, stand-off operation.

-

Interchangeable tool heads: suction plate, fork, winch, and more for multi-purpose use.

-

Side shift & vertical shift plus multi-directional rotation for fine alignment in tight tolerances.

-

Long operating time powered by high-capacity batteries to sustain full-day workflows.

Key Advantages – Aardwolf Glazing Robots

-

Precision at scale: side/vertical shifts and multi-directional rotation enable millimeter-accurate alignment of oversized panels.

-

Versatile by design: quick-swap tool heads (suction, fork, winch) expand the AGR-1000 from glazing to broader material handling.

-

Safer, leaner installs: remote control with speed tuning keeps operators at a safe distance while reducing crew size and fatigue.

-

Continuous productivity: high-capacity batteries deliver extended runtime, minimizing changeovers and downtime.