When planning a material handling system for your workshop, warehouse, or construction site, choosing between a jib crane and a gantry crane can significantly impact your workflow, budget, and efficiency. These cranes offer distinct advantages, but the ideal choice depends on your project requirements, space constraints, and usage patterns.

With decades of experience in lifting solutions, this guide draws on expertise, authoritativeness, and trustworthiness to offer a detailed comparison and selection advice. You’ll learn when to choose jib cranes vs. gantry cranes, with specific attention to crane types like freestanding, wall-mounted, mast-type jib crane, and more.

What Is a Jib Crane?

Table of Contents

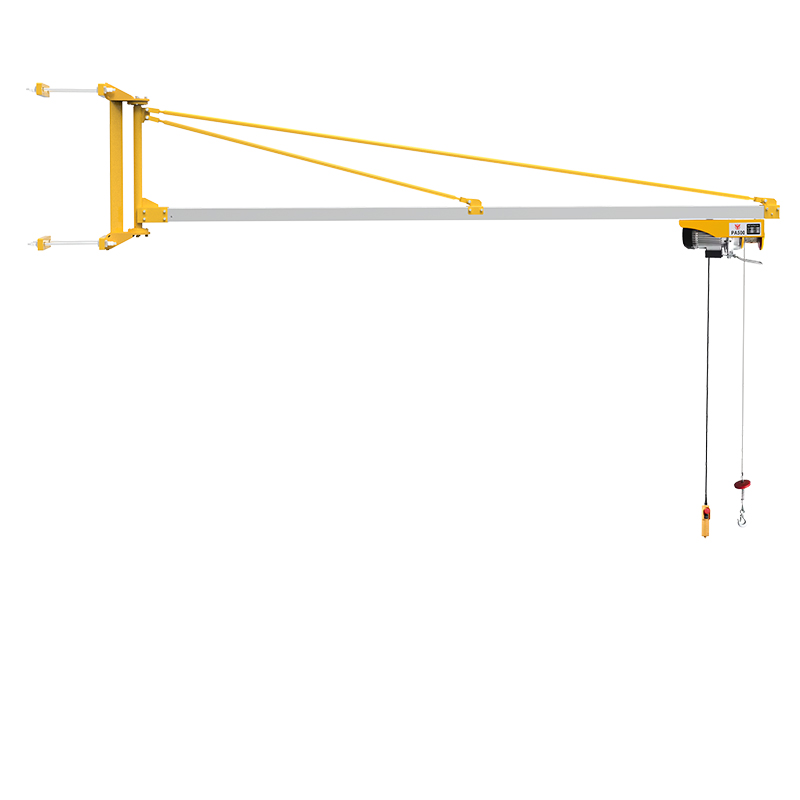

ToggleA jib crane features a horizontal arm (jib) that supports a hoist, usually mounted on a vertical mast or attached to a wall. It allows materials to be lifted and swung within a defined area, typically 180° to 360°.

Popular Types of Jib Cranes:

- Freestanding – Mounted to the floor with 360° rotation

- Wall-mounted – Saves space, suitable for fixed workstation lifting

- Mast-type – Mounted between floor and ceiling, no foundation needed

- Mast mounted – Reinforced support, used in tight vertical spaces

- Articulating – Dual-arm design, ideal for navigating around obstructions

🔗 For more jib cranes products

What Is a Gantry Crane?

A gantry crane includes a beam supported by two legs, often on wheels or rails. It can move across work areas and lift loads vertically, making it perfect for transporting heavy loads over larger distances.

Key Selection Factors: Jib Crane vs. Gantry Crane

1. Space and Layout

Jib Cranes

- Ideal for fixed workstation setups

- Wall-mounted and mast-type cranes save valuable floor space

- Compact and adaptable to tight areas

Gantry Cranes

- Requires clear floor space for movement

- Suitable for large, open layouts

- May obstruct workflows in smaller facilities

👉 See Jib Crane vs. Gantry Crane: What Works Better Indoors? for space optimization strategies.

2. Load Capacity Requirements

Jib Cranes

- Typical capacities: 250 kg to 5 tons

- Freestanding and mast-type cranes handle heavier loads

- Articulating jib cranes are suited for lighter precision lifts

Gantry Cranes

- Offers higher maximum load capacities (up to 100+ tons)

- Better suited for large-scale or heavy industrial applications

👉 Reference Jib Crane vs. Gantry Crane: Ideal Applications Compared for industry-specific use cases.

3. Installation and Setup

Jib Crane

- Wall-mounted or mast-type jib cranes require minimal setup

- Freestanding models need concrete foundations

- Quick and efficient installation with low disruption

Gantry Crane

- Requires a level surface or rail system

- Takes longer to install and configure

- Needs ample clearance for movement

👉 Learn safe installation practices in Jib Crane: Safety, Setup, and Maintenance

4. Mobility and Flexibility

Jib Crane

- Mostly stationary but offers rotational flexibility

- Articulating cranes can maneuver around obstacles

- Ideal for repetitive lifting in a fixed radius

Gantry Crane

- Fully mobile across floors or tracks

- Excellent for projects requiring long-distance horizontal movement

5. Cost and Long-Term Value

Jib Crane

- Lower initial cost (especially for wall-mounted or mast-type)

- Minimal ongoing maintenance

- Excellent ROI for localized material handling

Gantry Crane

- Higher initial investment

- Increased maintenance and operational costs

- Justified only for heavy or large-area lifting tasks

Recommended Scenarios

| Use Case | Recommended Crane Type |

|---|---|

| Repetitive tool loading at machines | Wall-mounted jib crane |

| Maintenance bay in workshop | Freestanding jib crane |

| Compact workspace with obstacles | Articulating jib crane |

| Large warehouse with long load movement | Gantry crane |

| Indoors with limited ceiling height | Mast-type or mast mounted jib crane |

| Outdoor shipyard or container loading | Gantry crane |

Questions to Ask Before Selecting

- What is the maximum weight you need to lift?

- Is the crane needed for a fixed location or multiple areas?

- What is the clearance height and floor space available?

- Is installation permanent or temporary?

- What is your budget and project timeline?

Final Thoughts: Jib Crane or Gantry Crane?

Both jib cranes and gantry cranes are invaluable lifting solutions—but their suitability hinges on your specific project needs.

Choose jib cranes if:

- You need localized lifting

- Space is limited

- You prefer lower installation and maintenance costs

- You’re lifting moderate loads (up to 5 tons)

Choose gantry cranes if:

- You need to move loads across large distances

- Your loads exceed 10 tons

- Your layout is open and permits full movement

🔍 Ready to equip your site with the right lifting solution? View for more jib cranes products to match your application.

More Expert Resources:

- Jib Crane: Safety, Setup, and Maintenance

- Jib Crane vs. Gantry Crane: What Works Better Indoors?

- Jib Crane vs. Gantry Crane: Ideal Applications Compared

Lift smart. Choose the crane that lifts your productivity and protects your budget.

Please log in to leave a comment.