Table of Contents

ToggleIntroduction: Are Refurbished Jib Cranes Worth It?

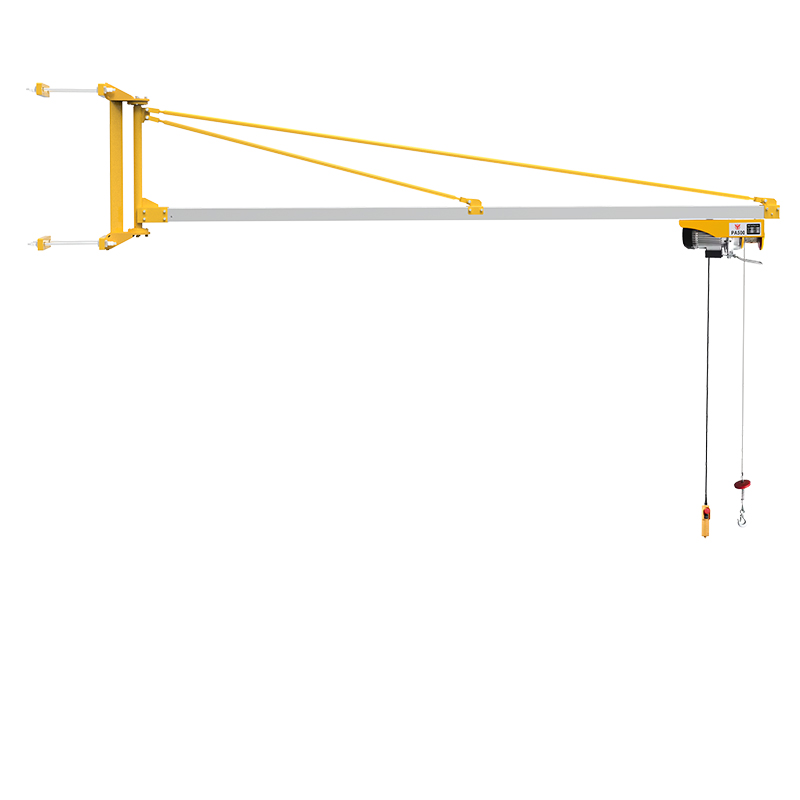

Refurbished jib cranes offer an appealing alternative for cost-conscious buyers who still demand operational reliability and lifting performance. With supply chain challenges and tighter capital budgets, businesses increasingly consider refurbished models as a viable solution. But how much can you really save? And what compromises, if any, are involved? This article explores the realistic jib crane price expectations for refurbished units, key considerations, and expert insights to guide your decision.

What Qualifies as a Refurbished Jib Crane?

A refurbished jib crane is a previously owned unit that has been inspected, repaired, cleaned, and sometimes upgraded for resale. Common sources include:

- Off-lease or retired from service

- Recovered from facility closures

- Trade-ins during equipment upgrades

A reputable refurbishment process may include:

- Disassembly and structural inspection

- Recoating or repainting

- Replacement of hoists, bearings, or control panels

- Load testing and certification to compliance standards

Typical Price Range: Refurbished vs. New

| Crane Type | New Price Range | Refurbished Price Range |

|---|---|---|

| Wall-Mounted (1 ton) | $3,500 – $7,000 | $2,000 – $4,500 |

| Freestanding (2 ton) | $7,000 – $12,000 | $4,000 – $7,500 |

| Articulating (custom) | $10,000 – $20,000+ | $6,000 – $12,000 |

Savings Potential: 30% to 50% off the new unit price, depending on age, condition, and included upgrades.

Key Benefits of Choosing a Refurbished Jib Crane

1. Lower Upfront Costs

The most obvious benefit is reduced capital expenditure, allowing businesses to reallocate funds toward other equipment or projects.

2. Faster Availability

Refurbished units are often available sooner than made-to-order new cranes, especially for standardized capacities and configurations.

3. Environmentally Sustainable

Reusing materials and components helps reduce industrial waste and aligns with ESG or sustainability goals.

Important Considerations Before Buying

1. Inspection and Testing History

Ensure the crane underwent load testing, structural inspection, and hoist performance evaluations. Reputable resellers should provide a refurbishment report and certification.

2. Component Upgrades

Check if high-wear parts like hoists, bearings, motors, or control systems were replaced or upgraded. Learn how these affect efficiency and safety.

See Jib Crane Price Impact of Energy-Saving Technology Add-ons for insights on how modern upgrades can influence pricing.

3. Warranty and Support

Unlike new cranes that often come with 1–5 year warranties, refurbished cranes may offer limited or 30–90 day support. Always review post-sale service terms.

4. Custom Fit and Compatibility

Older cranes may not suit your current installation environment. Be prepared for potential custom mounting adjustments or retrofitting.

If you require modifications, review the Jib Crane Price Estimates for Custom Fabrication Models to understand associated costs.

Typical Costs for Refurbishment-Related Services

| Service | Estimated Cost |

|---|---|

| Site inspection and compatibility check | $300 – $800 |

| Replacement of hoist/motor | $1,000 – $3,500 |

| Load testing and re-certification | $500 – $1,500 |

| Surface repainting or galvanizing | $600 – $2,000 |

Total refurbishment costs may add $1,000–$5,000 to the base price of a used crane.

Are Refurbished Cranes Energy-Efficient?

In most cases, older cranes lack modern efficiency features. However, if the unit is upgraded with VFDs, smart hoists, or high-efficiency motors, it can still meet today’s energy standards.

For long-term operational savings, compare against Jib Crane Price for Energy-Efficient Operation Models.

When to Choose Refurbished Over New

- You need a crane quickly for a short-term project

- Your lifting needs are low-frequency or low-intensity

- You are expanding or replacing an identical existing crane

- Budget restrictions prevent a new investment

Final Thoughts: A Smart Choice with Proper Due Diligence

Refurbished jib cranes offer excellent value—if sourced carefully and matched to your application. While the jib crane price is lower, success depends on inspecting the refurbishment quality, evaluating potential upgrade needs, and securing basic post-purchase support.

To explore quality crane systems for both standard and custom applications, visit Aardwolf’s range of jib cranes and connect with trusted specialists.

Please log in to leave a comment.