Table of Contents

ToggleIntroduction to Jib Crane Pricing Structures

Understanding the complete jib crane price involves more than just the base equipment cost. For buyers aiming to make informed investment_ decisions, it’s essential to consider both installation and hidden costs that can significantly affect total expenditure. This guide offers expert insights and trusted advice on how to anticipate and manage all the cost factors associated with jib crane purchases.

The True Cost of a Jib Crane: More Than Just the Price Tag

Many companies focus solely on the catalog price of a jib crane. However, the real cost includes multiple components:

- Equipment cost (crane structure, hoist, motor)

- Jib crane installation

- Customization or special features

- Site preparation and foundation

- Permits, inspections, and certifications

- Maintenance setup and training

Failing to budget for these components can lead to unforeseen expenses that inflate your total investment.

Base Jib Crane Price by Type

The base cost varies depending on the type and intended application. For a comprehensive overview of crane types and price tiers, see our Jib Crane Price Guide for Small Workshops and Warehouses.

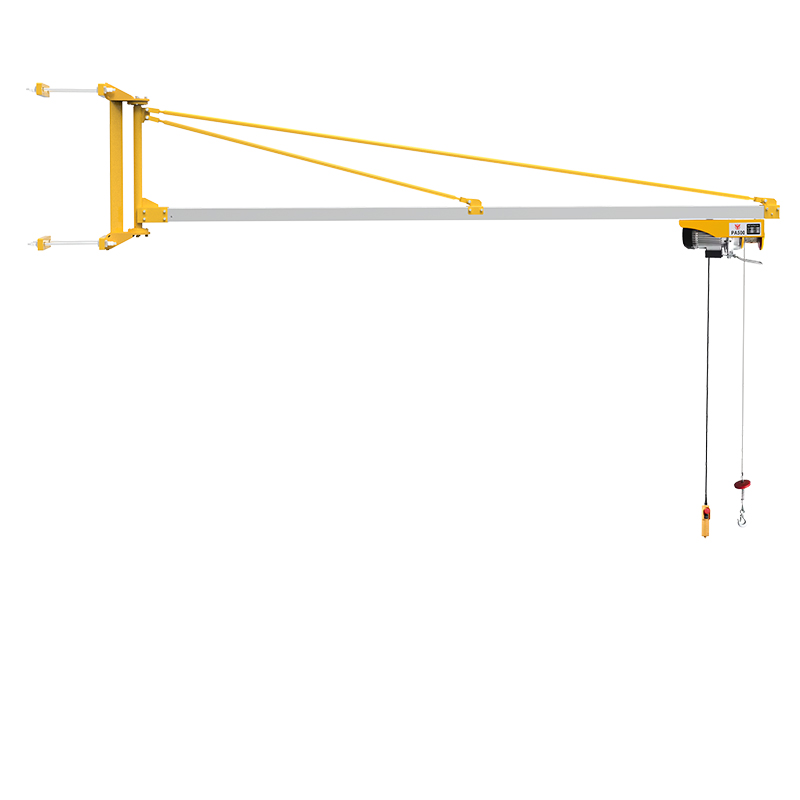

- Wall-Mounted Jib Cranes: Typically range from $1,500 to $8,000

- Freestanding Jib Cranes: Range from $5,000 to $25,000+

- Articulating Jib Cranes: Can cost between $4,000 and $15,000 depending on reach and load capacity

Jib Crane Installation Costs

Foundation and Structural Work

For freestanding cranes, reinforced concrete foundations are often required. This involves excavation, rebar installation, and curing time, with costs ranging from $1,000 to $5,000 or more depending on crane capacity and site conditions.

Labor and Assembly

Professional assembly by certified technicians can cost anywhere from $1,000 to $3,000. This includes erecting the jib crane, installing hoists, calibrating the system, and testing for safety compliance.

Electrical Setup

Motorized jib cranes or those requiring integration with facility control systems may involve electrical wiring and control panel installation—adding another $500 to $2,500 depending on complexity.

Permits and Inspection Fees

Depending on your region, you may need permits or certifications from safety authorities before commissioning a jib crane. These fees typically range from $200 to $1,000 but can vary based on local regulations.

Hidden Costs Often Overlooked

Custom Engineering or Modifications

If your jib crane requires specific customization—such as increased height, rotation angle adjustments, or unique load applications—expect additional design and manufacturing fees ranging from $1,000 to $5,000.

Training Programs

Proper use and maintenance require operator and technician training. Depending on the program’s depth and number of personnel involved, costs can range from $500 to $2,000. To get a clearer picture of training value, refer to Jib Crane Price Factors: Load Capacity, Span, and Rotation.

Ongoing Maintenance Setup

Budgeting for regular jib crane maintenance is crucial. Spare parts, tools, lubricants, and service calls may cost several hundred dollars annually. Planning your maintenance strategy from the start ensures safety and longevity.

Operational Cost Considerations

Downtime and Lost Productivity

Improper installation or lack of training may lead to downtime, which costs businesses in productivity losses. Investing upfront in quality setup and training mitigates these long-term operational costs.

Future Upgrades or Retrofits

As your operational needs grow, you may need to retrofit your jib crane with automation features or increased load capacity. While optional, these upgrades come with added costs that should be anticipated.

Tips for Cost-Efficient Jib Crane Investment

Compare Total Cost of Ownership (TCO)

Rather than focusing only on the purchase price, evaluate:

- Equipment cost

- Installation fees

- Annual maintenance

- Energy efficiency

- Operator training

This holistic view ensures a more accurate cost-benefit analysis. For buyers evaluating future pricing shifts, check our article on Jib Crane Price Trends in 2025: What Buyers Should Know.

Request Detailed Quotes from Vendors

Reputable suppliers will offer transparent, line-item quotes including installation, transport, and taxes. This prevents surprise fees and helps with accurate budgeting.

Consider Preconfigured Crane Packages

Some manufacturers offer preconfigured crane kits tailored for small workshops or standard warehouse applications. These packages can reduce both purchase and installation costs while ensuring quicker setup.

Choosing a Trustworthy Crane Provider

Work with providers who demonstrate proven industry expertise, strong customer support, and transparent pricing. Aardwolf offers a wide selection of jib crane products along with installation support and post-sale service—ensuring reliable, long-term value.

Conclusion: Budgeting Smart for a Successful Crane Investment

Accurately assessing jib crane price goes far beyond the listed equipment cost. By factoring in installation, training, maintenance, and potential hidden expenses, businesses can make smarter purchasing decisions that ensure safety, reliability, and return on investment. Anticipating these costs ensures a smoother procurement process and a more successful long-term operation.

Please log in to leave a comment.