In industrial environments where lifting, moving, and positioning heavy materials is a routine operation, the jib crane stands out as a compact, reliable, and flexible material handling solution. Whether it’s a wall-mounted, free standing, or articulated arm jib crane, regular maintenance is not just about protecting your investment—it’s about ensuring a safe and productive workplace.

This article outlines actionable jib crane maintenance tips that prioritize workplace safety, reduce risk of failure, and extend the operational lifespan of your equipment. With insights backed by industry standards and real-world engineering experience, this guide is essential for safety officers, plant managers, and maintenance professionals.

Table of Contents

ToggleWhy Jib Crane Maintenance is Essential to Workplace Safety

Mechanical lifting equipment is subject to significant stress and fatigue over time. Without proper inspection and upkeep, jib cranes can develop hidden structural faults, control malfunctions, or load-handling issues—all of which pose severe safety risks. Routine jib crane maintenance ensures:

- Operator and bystander safety

- Compliance with OSHA and ISO standards

- Early identification of wear or failure points

- Reduced equipment downtime and costly repairs

- Improved lifting accuracy and mechanical reliability

A single oversight in crane maintenance can lead to dropped loads, uncontrolled movements, or even catastrophic structural failure. That’s why maintenance is a safety-first initiative, not just a mechanical one.

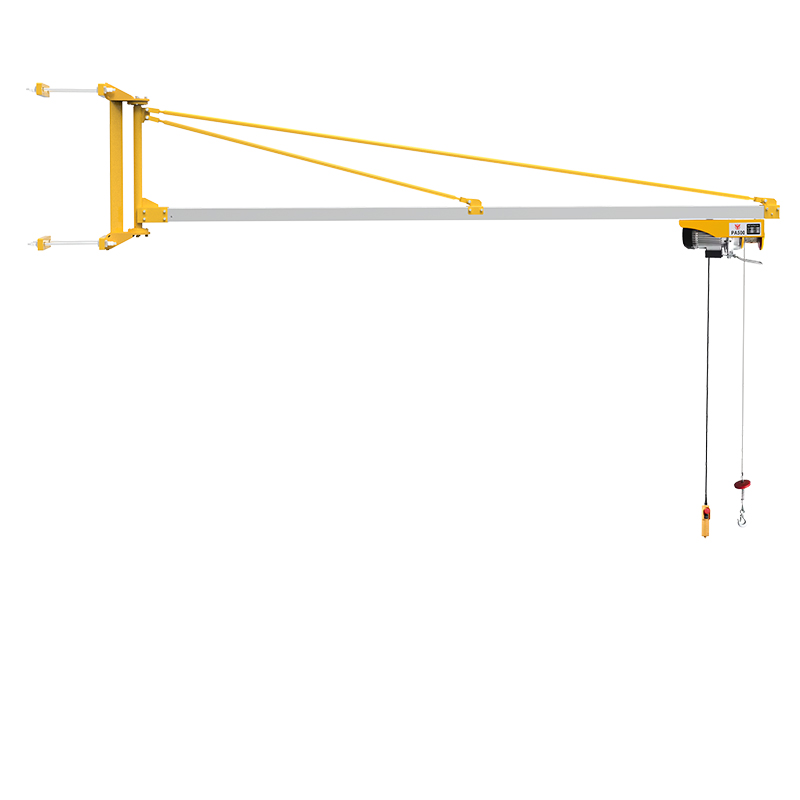

Understanding the Different Jib Crane Types and Maintenance Needs

Not all jib cranes are the same—and neither are their maintenance protocols. Here’s a breakdown of the major jib crane types and what safety-oriented maintenance involves for each:

Wall-Mounted Jib Crane

These cranes are attached to building columns or walls and serve localized work areas. Regular checks should include:

- Verifying mounting bolt integrity

- Inspecting for cracks in concrete or masonry

- Ensuring boom arm rotation is smooth and unobstructed

Free Standing Jib Crane

Installed independently on the factory floor, these cranes offer 360° coverage and high flexibility. Maintenance should cover:

- Base anchorage inspection and torque checks

- Alignment of vertical mast

- Periodic foundation stress assessments

Articulated Arm Jib Crane

These cranes offer multiple joints for increased flexibility and movement in tight spaces. Special maintenance considerations include:

- Greasing all pivot points and bearings

- Checking for joint misalignment or unusual wear

- Testing full articulation under load

Understanding your specific crane configuration helps develop a maintenance plan that aligns with its mechanical behavior and usage intensity.

Top Jib Crane Maintenance Tips for a Safer Workplace

1. Conduct Pre-Shift Visual Inspections

Start every workday with a brief walkaround. Look for visible signs of:

- Structural fatigue, such as cracks, rust, or deformation

- Loose bolts, worn welds, or missing fasteners

- Frayed cables, kinked chains, or misaligned trolleys

Document any irregularities and report them immediately. These small checks can prevent major incidents later.

For a comprehensive guide, refer to the Jib Crane Maintenance Checklist for Daily Inspections.

2. Verify Control System Functionality

Test all operational and emergency controls before each shift. This includes:

- Lift, lower, and trolley direction buttons

- Emergency stop switches

- Warning lights and audio signals

Unresponsive or delayed controls should never be ignored—they’re a common precursor to unsafe operations.

3. Lubricate Moving Components Regularly

Friction and wear are inevitable in components like:

- Boom arm pivots

- Trolley wheels and track systems

- Swivel hooks and bearings

Follow the manufacturer’s lubrication schedule and use only approved lubricants to maintain smooth, safe movement.

4. Monitor the Load Handling Mechanism

Pay close attention to the hoist, hook, and lifting medium. Look for:

- Uneven hoist operation or noisy lifting

- Hook deformation or unlocked safety latches

- Slipping or sagging during load holding

Failing hoist systems can result in uncontrolled drops—one of the most dangerous scenarios in crane operation.

5. Inspect Limit Switches and Safety Devices

Limit switches prevent over-travel during lifting and lowering. These should be:

- Calibrated properly

- Tested monthly under supervision

- Reset or replaced immediately if malfunctioning

Additional safety devices such as load sensors and overload alarms should also be verified.

For extended insights, review the Essential Jib Crane Maintenance Tips to Maximize Lifespan.

Scheduled Maintenance and Safety Compliance

Besides daily checks, longer-term scheduled maintenance is critical to prevent hidden failures.

Monthly or Quarterly Maintenance

- Inspect structural welds via magnetic particle or dye penetrant testing

- Conduct motor amperage and temperature assessments

- Test lifting components under controlled load conditions

Annual Safety Audits

- Engage certified inspectors to assess the crane’s structural integrity

- Check compliance with local occupational health and safety laws

- Review crane documentation, service logs, and incident reports

A consistent maintenance schedule aligned with usage frequency and load capacity will keep both your equipment and employees safe.

The Connection Between Installation and Maintenance Safety

Proper jib crane installation sets the foundation for long-term operational safety. Improper alignment, weak anchoring, or low-quality foundation work can compromise even the best maintenance efforts. Best practices include:

- Following OEM installation guidelines

- Hiring qualified structural engineers

- Performing post-installation testing and validation

For safe and efficient installation, always work with certified professionals who understand your building’s load-bearing capacity and workflow dynamics.

Tips for Operator Involvement in Crane Maintenance

Your operators are on the front lines of crane safety. They should be empowered and trained to:

- Report unusual noises, movement patterns, or response delays

- Participate in minor inspection tasks

- Understand the limits of the crane and operate within capacity

A strong maintenance culture begins with educated, observant operators who treat the equipment as their responsibility—not just a tool.

Choosing Low-Maintenance Jib Crane Designs

To reduce your maintenance burden from the start, select crane models designed for easy access, durable components, and minimal mechanical complexity. Look for:

- Enclosed electrical systems

- Grease-free bearings

- Modular boom arms

Explore more jib crane products to find models built with long-term durability and ease of maintenance in mind.

Learn More: Expert Maintenance Resources

For deeper insights and long-term planning, explore these related resources:

- Jib Crane Maintenance Guide to Extend Equipment Lifespan

- Essential Jib Crane Maintenance Tips to Maximize Lifespan

These articles provide practical strategies for advanced inspections, lifecycle planning, and predictive maintenance techniques.

Conclusion: Maintenance Is Safety

A well-maintained jib crane is not just a reliable piece of equipment—it’s a cornerstone of workplace safety. Implementing a structured, proactive jib crane maintenance program ensures the protection of both assets and personnel. Whether you’re managing a small production line or a large industrial operation, these tips will help you prevent accidents, reduce downtime, and support sustainable operations.

Prioritize maintenance. Protect your people. Preserve your equipment.

Please log in to leave a comment.