Table of Contents

ToggleIntroduction

Implementing data-driven jib crane maintenance practices significantly enhances asset return on investment (ROI) for industrial operations. Effective maintenance analytics provide insights that help organizations proactively manage crane performance, reduce downtime, and extend equipment lifespan. This article delivers expert guidance based on industry experience, highlighting practical analytics-driven approaches to jib crane maintenance.

Understanding the Importance of Jib Crane Maintenance

Enhancing Operational Efficiency

Proper jib crane maintenance ensures cranes perform optimally, leading to smoother operational workflows and increased productivity. Regular maintenance analytics highlight potential improvements, guiding maintenance efforts to areas requiring immediate attention.

Preventing Costly Repairs

Neglected maintenance often leads to significant downtime and high repair costs. Adopting data-driven practices, such as those detailed in Jib Crane Maintenance Practices That Prevent Costly Repairs, can substantially reduce operational disruptions and financial losses.

Key Analytics for Effective Maintenance

Predictive Analytics

Predictive analytics employs historical and real-time data to foresee potential mechanical and operational failures. These insights enable operators to schedule maintenance proactively, rather than reactively, thus minimizing unexpected downtime.

Critical metrics include:

- Usage frequency and load analysis

- Wear and tear trend tracking

- Component lifespan predictions

Performance Monitoring

Continuous performance monitoring identifies irregularities promptly, allowing timely interventions. Metrics include:

- Load handling efficiency

- Frequency of maintenance interventions

- Downtime occurrences

Cost Analysis and ROI Metrics

Regular analysis of maintenance-related expenditures versus performance outcomes provides clear insights into ROI. Key analytics include:

- Cost-per-hour of crane operation

- Breakdown and emergency repair frequency

- Overall maintenance investment versus operational uptime

Types of Jib Cranes and Maintenance Analytics Considerations

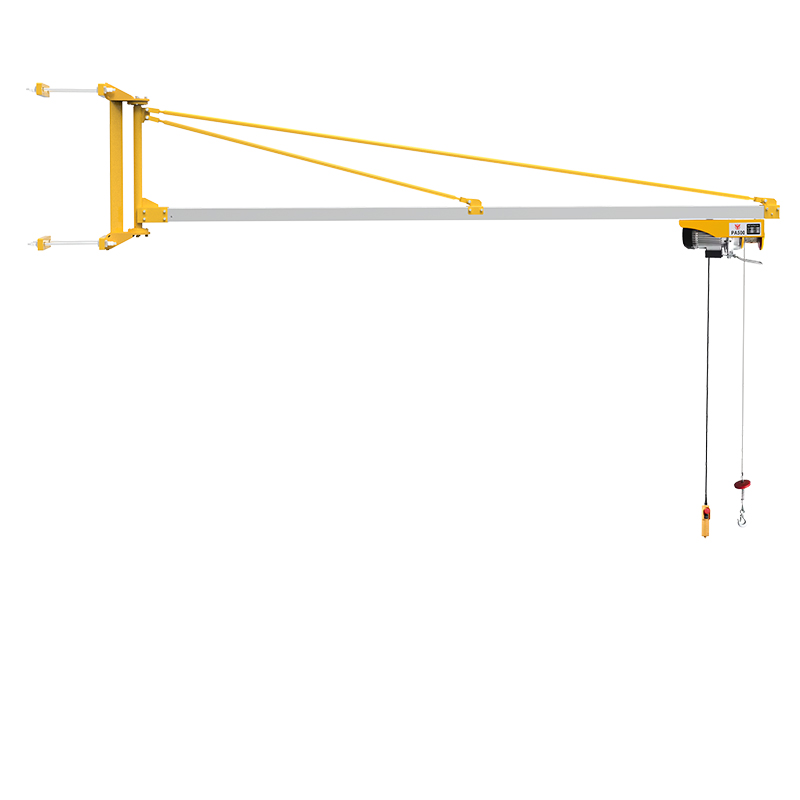

Wall-Mounted Jib Cranes

For wall-mounted jib cranes, analytics should focus on structural integrity, mounting stability, and rotation efficiency. Regular data collection on anchor bolt conditions and rotation mechanisms ensures sustained performance.

Freestanding Jib Cranes

Maintenance analytics for freestanding jib cranes must emphasize foundational stability, load capacity analytics, and rotational smoothness. Constant monitoring of foundation stability and bearing wear is crucial.

Articulating Jib Cranes

Articulating jib cranes require specialized analytics focusing on joint conditions, pivot points, and hinge integrity. Wear-and-tear analytics are especially vital for ensuring precision in operation.

Practical Steps for Implementing Jib Crane Maintenance Analytics

Establish a Data Collection Framework

To effectively leverage analytics, establish consistent data collection methods focusing on essential maintenance metrics. Tools and products used in maintenance should be standardized and chosen based on reliability, as detailed in Jib Crane Maintenance Tools and Products You Should Use.

Integrate Predictive Maintenance Software

Implementing predictive maintenance software streamlines data analysis. Such platforms can efficiently process collected data, providing actionable insights that enable timely and informed maintenance decisions.

Conduct Regular Reviews and Adjustments

Maintenance analytics should be reviewed regularly to identify trends and adapt maintenance strategies accordingly. Continuous improvement based on analytical insights ensures long-term equipment reliability and improved ROI.

Sustainability and Maintenance Analytics

Jib crane maintenance analytics also plays a crucial role in sustainability. Analyzing sustainability metrics, including energy efficiency, waste reduction, and eco-friendly product usage, enhances operational sustainability. Sustainable analytics can include:

- Usage of biodegradable lubricants

- Frequency of part recycling

- Energy consumption tracking per crane

Training and Education Driven by Analytics

Analytics-driven insights can guide comprehensive operator training programs, focusing on areas requiring enhanced attention. Educated operators contribute significantly to reducing operational errors and improving crane performance.

For a targeted maintenance strategy, operators can explore Jib Crane Maintenance Strategy for Small Industrial Sites for in-depth strategies.

Real-world Benefits of Analytics-driven Jib Crane Maintenance

Reduced Operational Costs

Maintenance analytics reduce operational costs by significantly lowering the frequency and severity of breakdowns, ensuring consistent productivity.

Improved Equipment Lifespan

Proactive maintenance informed by analytics dramatically extends jib crane lifespan, ensuring better asset utilization and a higher ROI.

Enhanced Safety

Analytics-driven maintenance ensures cranes are consistently maintained in optimal conditions, significantly reducing the risk of accidents and improving overall workplace safety.

Selecting a Reliable Maintenance Analytics Partner

Choosing the right partner is crucial. Trusted providers such as Aardwolf offer extensive ranges of crane products and expert guidance on analytics integration, fostering enhanced trustworthiness and authoritative support.

Conclusion

Implementing robust jib crane maintenance analytics transforms asset management, significantly boosting ROI, enhancing safety, and reducing operational costs. By employing predictive analytics, continuous monitoring, and regular reviews, organizations ensure sustained operational excellence and reliability, maximizing the long-term benefits and applications of jib cranes.

Please log in to leave a comment.