When it comes to safe material handling, knowing your jib crane‘s load capacity isn’t optional—it’s essential. Whether you’re operating a freestanding, a wall-mounted, or a more complex articulating jib crane, understanding load limits and adhering to safety protocols ensures performance, longevity, and protection from catastrophic failure.

In this guide, we’ll break down:

- Jib crane load limit fundamentals

- The impact of crane type on capacity

- Proven safety practices to prevent accidents

- Installation insights that ensure structural integrity

📦 Looking for equipment that meets your site’s lifting requirements? Browse jib crane products now.

Table of Contents

ToggleWhy Load Limits Matter for Every Jib Crane

Exceeding a jib crane’s rated capacity can lead to:

- Structural damage

- Swing arm failure

- Foundation cracking

- Injury or fatality

- Prolonged downtime

A well-planned jib crane installation is engineered to handle specific loads with built-in safety factors. Pushing those limits is not only dangerous—it also voids your warranty and may violate OSHA and ANSI B30.11 safety standards.

🛠 Planning a safe setup? See Jib Crane Installation Planning for Indoor and Outdoor Use

Common Jib Crane Load Capacities by Type

| Crane Type | Typical Load Capacity Range |

|---|---|

| Freestanding Jib Crane | 500 kg – 5,000 kg |

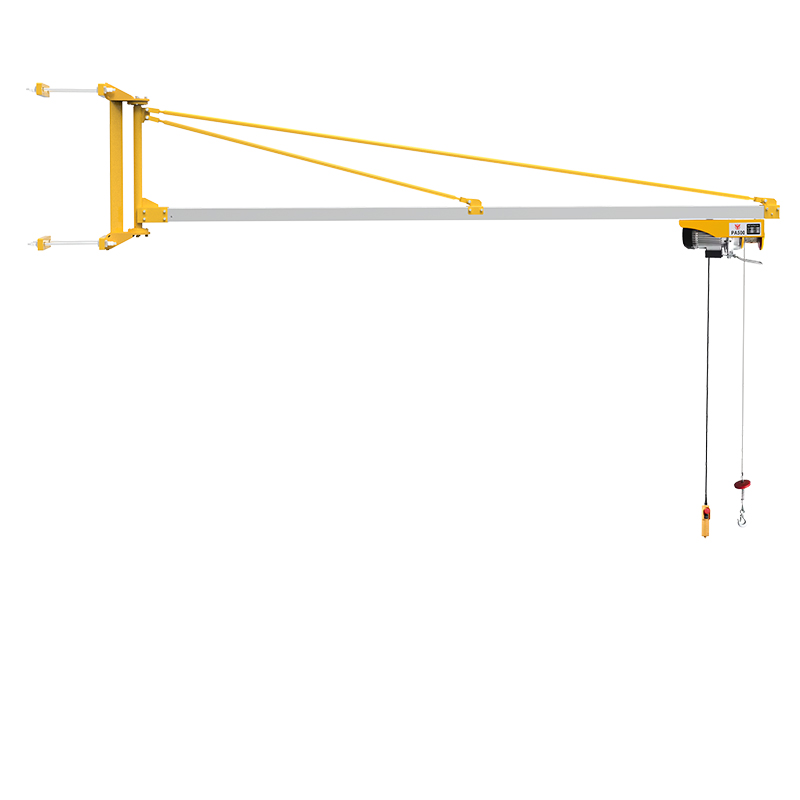

| Wall-Mounted Jib Crane | 250 kg – 2,000 kg |

| Mast-Type Jib Crane | 500 kg – 4,000 kg |

| Mast-Mounted Jib Crane | 500 kg – 3,000 kg |

| Articulating Jib Crane | 150 kg – 1,000 kg |

Note: Capacities vary by span length, boom material, and hoist system. Always refer to manufacturer documentation.

Key Factors That Influence Load Limits

1. Crane Arm Length and Span

Longer boom arms reduce capacity due to increased moment force. A 5m arm typically supports less than a 3m arm, even if the column remains the same.

2. Mounting Style

- Wall-mounted jib cranes depend on the building structure—overload may damage walls.

- Freestanding models rely on correctly engineered foundations for full-rated loads.

- Mast-type and mast-mounted cranes require floor and ceiling support and can fail if one anchor point is weak.

3. Slewing Angle and Rotation

Larger rotation arcs introduce torsional stress. Many articulating designs reduce this risk by limiting swing to specific work zones.

Top Safety Tips to Prevent Overload and Injury

1. Know the Rated Load—And Respect It

Ensure all operators are trained on maximum working load (MWL) for the specific crane type and hoist used. Use visible capacity plates on every unit.

2. Use a Load Cell or Crane Scale

Modern jib cranes can integrate load cells that warn or lock out operations when nearing the limit.

3. Check the Hoist Capacity Separately

A 2-ton crane with a 1-ton hoist still maxes out at 1 ton. Mismatched hoists are a common error.

🧰 Avoid misconfigurations: Jib Crane Installation Errors That Can Lead to Downtime

4. Perform Pre-Shift Inspections

- Look for cracks at the base plate

- Check for boom arm sag or misalignment

- Test trolley motion for smoothness

- Ensure the hoist brake is responsive

5. Monitor Swing Radius and Obstructions

Overhead beams or sidewalls may prevent the crane from fully rotating, placing unexpected stress on the arm.

Load Distribution and Safe Operation Angles

Never lift a load:

- Too far out on the boom arm (max load should be centered)

- While swinging rapidly (adds dynamic force)

- While boom or hoist is out of alignment

🕓 Learn how proper timing supports safe installs: Jib Crane Installation Timeline: How Long Does It Take?

Installation: The Foundation of Load Integrity

Even a perfectly rated crane will fail if the installation was flawed.

For example:

- Freestanding jib cranes must have a reinforced concrete foundation to resist base bending under high loads.

- Wall-mounted jib cranes may tear off drywall or unreinforced masonry when loaded.

- Mast-type cranes with inadequate ceiling connections could collapse with minimal force.

📋 Explore more: Jib Crane Installation Planning for Indoor and Outdoor Use

Real-World Warning Signs of Overload Risk

| Symptom | Potential Issue |

|---|---|

| Jib arm flexes under load | Overloaded or boom too long |

| Uneven hoist travel | Misaligned trolley or arm sag |

| Floor cracks at anchor base | Foundation failing due to excess load |

| Hoist motor overheating | Excessive weight or hoist misalignment |

🔍 These are red flags. Stop operation and inspect immediately.

Trust & Experience: What Makes a Safe Setup?

When selecting equipment and planning the layout, ensure your provider:

- Has experience installing all types of jib cranes

- Understands load charts and hoist specs

- Offers after-installation inspection and load testing

- Can verify compliance with ANSI/OSHA regulations

If not, your operation is at risk.

📞 Start here: Jib Crane Installation Errors That Can Lead to Downtime

Final Thoughts: Safety Is Capacity Plus Planning

The safe use of jib cranes requires more than just reading a load chart. It’s about a holistic approach—selecting the right crane type, planning the installation properly, following capacity rules, and training staff to respect operating limits.

Crane downtime, injuries, and damage are preventable. All it takes is the discipline to follow safety best practices and the knowledge to spot risks early.

🔗 Want reliable, capacity-rated lifting equipment? Explore for more jib cranes products today.

Related Articles:

- Jib Crane Installation Errors That Can Lead to Downtime

- Jib Crane Installation Planning for Indoor and Outdoor Use

- Jib Crane Installation Timeline: How Long Does It Take?

Lift responsibly. Train regularly. Respect the limit.

Please log in to leave a comment.