In today’s fast-paced industrial environments, efficient material handling isn’t just a competitive advantage—it’s a necessity. Whether in a warehouse, manufacturing plant, or shipyard, lifting tasks must be both safe and precise. That’s where jib crane applications come into play. These cranes are designed to simplify localized lifting tasks, reduce physical strain, and improve workplace safety across various sectors.

This guide explores the most effective jib crane applications, supported by expert insights into types, sectors, and real-world use cases. This article helps decision-makers choose the right lifting solution.

🏗️ Looking to upgrade your material handling system? Explore jib crane products built for reliability and performance.

Table of Contents

ToggleWhat Are Jib Cranes?

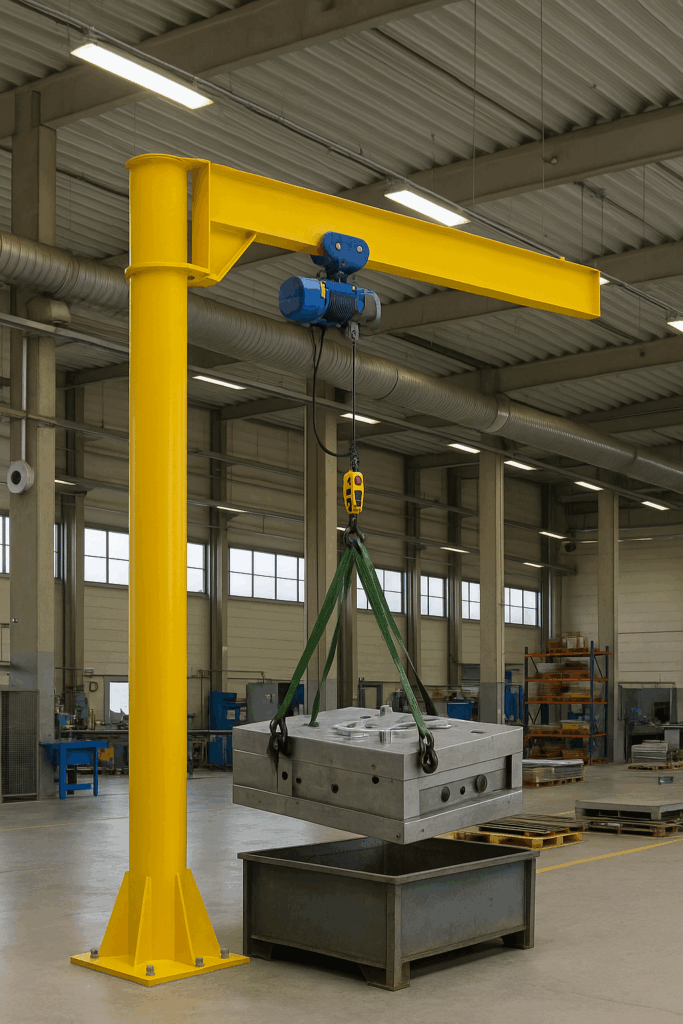

A jib crane is a type of material handling device consisting of a horizontal arm (or jib) that supports a hoist. Mounted on a vertical support (floor, wall, or column), the jib can rotate to move loads within a defined radius. Their compact and flexible design makes them ideal for areas where space is limited or where repetitive lifting occurs.

Why Are Jib Crane Applications Critical?

Jib cranes address key challenges in industrial lifting:

- They reduce worker fatigue and injury

- Improve load placement accuracy

- Operate in confined spaces with minimal obstruction

- Speed up repetitive lifting processes

Their versatility and range of configurations allow them to adapt to diverse industries with unique operational needs.

Types of Jib Cranes Used in Modern Applications

| Crane Type | Rotation | Best Use Case |

|---|---|---|

| Freestanding Jib Crane | 360° | Open floor spaces, general manufacturing |

| Wall-Mounted Jib Crane | 180°–200° | Along assembly lines or packing stations |

| Mast-Type Jib Crane | 360° | High-ceiling facilities without floor anchors |

| Mast Mounted Jib Crane | 360° | Buildings with structural support columns |

| Articulating Jib Crane | Variable | Confined or complex workstations |

Each crane type is designed for specific applications where space, load weight, or maneuverability are unique concerns.

Jib Crane Applications by Sector

1. Manufacturing

Manufacturing plants rely heavily on jib cranes for:

- Loading and unloading CNC machines

- Transporting assembly components

- Positioning tools and fixtures for welding or machining

Both freestanding and articulating jib cranes are common in these environments.

🔧 For deeper insights: Jib Crane Applications: Best Use Cases in Manufacturing

2. Warehousing and Logistics

In warehousing, jib cranes help manage:

- Pallet lifting near docks

- Repetitive loading and unloading tasks

- Equipment positioning at packing stations

Wall-mounted and mast-type jib cranes are often installed along pick-pack lines or inside truck bays.

🚚 Learn more in Jib Crane Applications in Warehousing and Logistics

3. Automotive and Aerospace

Jib cranes assist with:

- Handling engines and chassis components

- Lifting aerospace parts into alignment

- Installing subassemblies in tight work cells

These applications demand precise, stable lifting—ideal for mast-mounted or articulating jib cranes.

4. Fabrication and Metalworking

From bending steel sheets to transferring heavy parts between stations, freestanding jib cranes are integral to fabrication workflows. Their full-rotation swing makes them perfect for feeding laser cutters, welding tables, or punch presses.

5. Energy and Utilities

In maintenance shops and field repair areas, wall-mounted or mast-type cranes help lift:

- Generators and transformers

- Hydraulic pumps and HVAC units

- Control panels and cable spools

This reduces the need for mobile cranes or forklifts in tight utility spaces.

6. Marine and Shipbuilding

Freestanding or mast-mounted jib cranes support:

- Deck equipment positioning

- Cargo loading in dockyards

- Tool and parts handling below deck

Their rugged design and customizable reach make them reliable in salt-air or outdoor environments.

Safety Considerations for Jib Crane Applications

Safe operation is vital in all lifting environments. Key considerations include:

1. Understanding Load Limits

Every crane has a designated load rating. Overloading can lead to structural failure or hoist malfunction.

2. Proper Installation

A crane is only as safe as its installation. Poor anchoring or incorrect boom positioning can lead to serious accidents.

3. Routine Inspection

Check wear points like:

- Pivot joints

- Hoist brakes and cables

- Base plates and wall mounts

⚠️ Avoid critical mistakes: Jib Crane Applications Across Key Industrial Sectors

Choosing the Right Crane for the Job

| Application Type | Suggested Crane |

|---|---|

| Confined workstations | Articulating Jib Crane |

| Long wall or corridor | Wall-Mounted Jib Crane |

| Heavy-duty floor lifting | Freestanding or Mast-Type |

| Ceiling-integrated areas | Mast Mounted Jib Crane |

| Modular production setups | Portable or column-mounted models |

Evaluate based on:

- Load weight

- Space constraints

- Rotation angle needed

- Proximity to walls or ceiling supports

Expert Tip: Integrating Jib Cranes with Other Systems

For maximum efficiency:

- Integrate jib cranes near conveyor belts

- Use them alongside gantry or overhead cranes in hybrid workflows

- Sync with hoists rated for variable speeds and smart controls

Final Thoughts: Smart Lifting Starts with Smart Planning

Jib crane applications are essential across sectors where safety, speed, and space are top priorities. Their ability to simplify complex lifting tasks makes them an indispensable asset in both heavy-duty and precision industries.

By selecting the right crane type, ensuring proper installation, and training staff on safe operation, you can transform material handling from a risk into a strength.

🔍 Ready to explore options? Visit jib crane products to find models tailored to your operations.

Please log in to leave a comment.