In modern manufacturing environments, where efficiency, safety, and productivity are essential, jib crane applications have become increasingly vital. These systems offer not only speed and precision but also the flexibility to operate effectively in confined workspaces. As a result, jib cranes stand out as one of the most reliable and versatile lifting solutions available today.

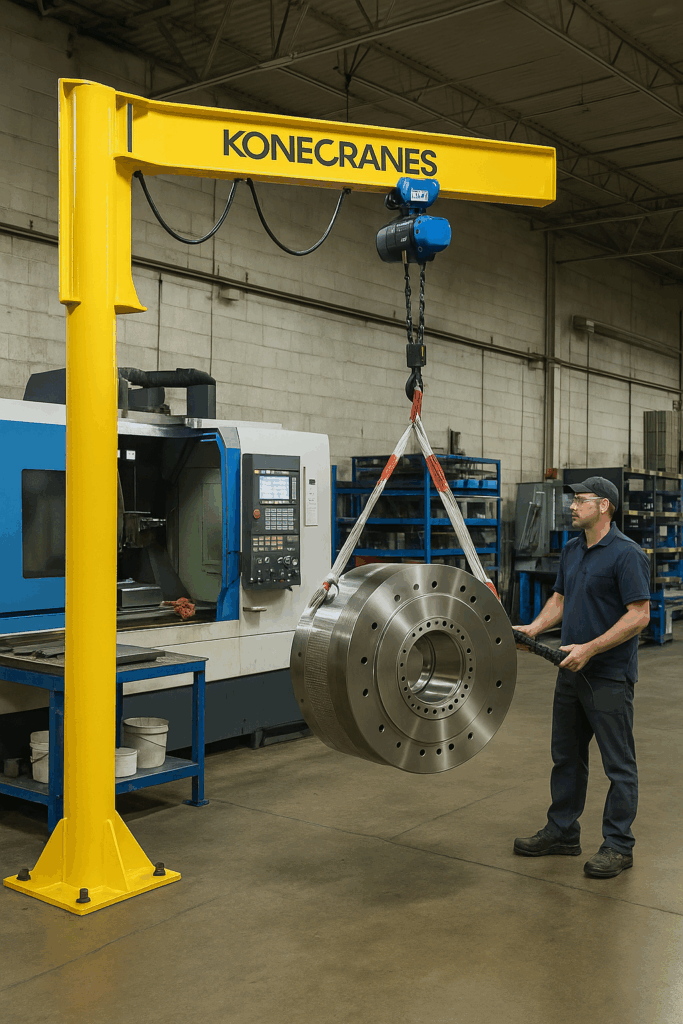

From light-duty lifting tasks to high-capacity material transport, jib crane applications are deeply integrated into various stages of the manufacturing process. Whether it’s an articulating jib crane near a CNC machine or a freestanding jib crane on an assembly floor, manufacturers rely on these cranes for localized, safe, and controlled lifting.

📦 Interested in equipment options? Explore jib crane products from Aardwolf.

Table of Contents

ToggleWhat Is a Jib Crane?

A jib crane is a lifting device with a horizontal arm (jib or boom) that supports a hoist. It rotates around a vertical axis and is commonly mounted on a column, wall, or mast. Jib cranes are ideal for workstations requiring repetitive lifting in a defined area, offering superior maneuverability compared to overhead or gantry cranes.

Why Jib Cranes Are Essential in Manufacturing

In manufacturing settings, lifting systems must be precise, quick, and non-disruptive to other processes. Jib cranes meet these needs because they:

- Improve production flow by reducing bottlenecks

- Allow safe material movement without forklifts

- Reduce worker fatigue and injury

- Fit compact or obstructed workspaces

- Offer cost-effective alternatives to full overhead cranes

✅ Manufacturers across sectors choose jib cranes for their reliability and adaptability.

Types of Jib Cranes and Their Manufacturing Use Cases

1. Freestanding Jib Crane

Use Case: General lifting in open-floor production areas

- Mounted on a reinforced concrete foundation

- Offers 360° rotation for maximum range

- Common in large-scale manufacturing zones where coverage is crucial

2. Wall-Mounted Jib Crane

Use Case: Assembly lines or machines near perimeter walls

- Fixed to structural walls or columns

- Offers 180°–200° swing arc

- Saves valuable floor space while increasing work cell efficiency

3. Mast-Type Jib Crane

Use Case: High-bay facilities or centralized workstations

- Supported by floor and ceiling (no foundation bolts)

- Offers 360° rotation

- Ideal for integrating lifting tools without compromising workspace flow

4. Mast Mounted Jib Crane

Use Case: Heavy-duty machine shops with strong building support

- Attached to vertical columns or pillars

- Customizable for longer booms and higher capacity

- Durable solution for repeated high-load cycles

5. Articulating Jib Crane

Use Case: Welding bays, tool stations, inspection areas

- Features two swivel arms for maximum flexibility

- Navigates around machines, corners, and obstructions

- Enables pinpoint load placement in compact or complex setups

📌 For broader context, see Jib Crane Applications: Where and How They’re Used Most

Jib Crane Applications Across Manufacturing Functions

1. Component Handling at CNC and Milling Machines

Operators frequently move heavy parts in and out of precision machines. Wall-mounted or articulating jib cranes can be positioned adjacent to equipment, enabling fast, safe transfers without forklifts or hand-lifting.

2. Workstation Assembly Support

Freestanding or mast-type jib cranes are used to assist in assembling large parts like engines, gearboxes, or frame structures. They can serve individual cells or multiple bays when strategically positioned.

3. Tool & Die Maintenance

Heavy dies, molds, and tools are commonly lifted during setup and teardown. A mast mounted jib crane above the tool room ensures safe lifting, even with limited access.

4. Material Transfer Between Conveyor Zones

Moving finished or semi-finished parts from one process to another is streamlined using articulating cranes, which offer dynamic movement along complex paths between conveyors or work tables.

5. Packing & Palletizing Operations

End-of-line areas benefit from wall-mounted cranes or compact freestanding systems to lift finished products onto pallets or into boxes, particularly when dealing with awkward or heavy loads.

🏭 For warehouse and logistics use cases, see Jib Crane Applications in Warehousing and Logistics

Advantages of Using Jib Cranes in Manufacturing

| Benefit | Impact |

|---|---|

| Space efficiency | Fits tight spaces without disrupting workflow |

| Cost-effective installation | Lower investment than overhead crane systems |

| Worker safety | Reduces strain, injury risk, and heavy manual lifting |

| Localized control | Minimizes traffic from forklifts or mobile cranes |

| Load precision | Ideal for aligning parts into fixtures or machines |

Safety and Load Handling Considerations

Manufacturers must ensure cranes are:

- Installed according to load capacity guidelines

- Routinely inspected for wear, alignment, and anchor integrity

- Operated by trained personnel aware of boom swing, max load, and lifting height

⚠️ Learn more: Jib Crane Load Limits & Safety Tips You Shouldn’t Ignore

Common Manufacturing Sectors Using Jib Cranes

| Industry | Jib Crane Type Commonly Used |

|---|---|

| Automotive Manufacturing | Freestanding, Mast Mounted |

| Aerospace & Aviation | Articulating, Wall-Mounted |

| Heavy Equipment Assembly | Freestanding, Mast-Type |

| Electronics Manufacturing | Wall-Mounted, Articulating |

| Tool & Die Production | Mast Mounted, Wall-Mounted |

| Metal Fabrication | Freestanding, Articulating |

🏗 Discover broader sector trends: Jib Crane Applications: Top Industries That Rely on Them

Final Thoughts: Smarter Lifting for Lean Manufacturing

From streamlining operations to improving worker safety, jib cranes are indispensable in today’s fast-paced, high-precision manufacturing world. When installed correctly and matched to the application, they drastically reduce downtime, boost productivity, and enhance operational flexibility.

Whether you’re building cars, assembling electronics, or fabricating steel structures, there’s a jib crane solution designed to meet your exact needs.

🎯 Ready to upgrade your lifting systems? Explore jib crane products engineered for manufacturing excellence.

Please log in to leave a comment.