In today’s fast-paced industrial environments, efficiency and productivity are top priorities. One of the most significant tools aiding in streamlined operations is the small jib crane. Compact, flexible, and capable of handling repetitive lifting tasks with ease, small jib cranes are revolutionizing workflow dynamics in assembly lines, especially where space is tight and precision matters.

Table of Contents

ToggleWhat Is a Small Jib Crane?

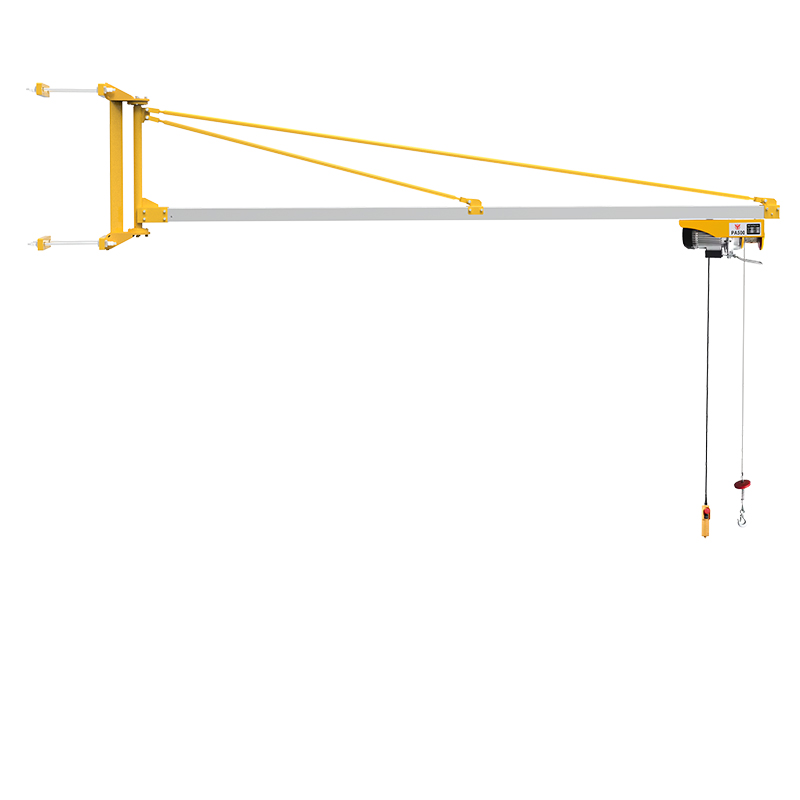

A small jib crane is a type of material lifting device featuring a horizontal boom mounted to a vertical mast or wall bracket. The boom rotates to move objects within a specific radius, making it ideal for confined spaces like assembly lines, workshops, or manufacturing floors.

Depending on the design, a small jib crane can be wall-mounted, floor-mounted, or attached to an existing structure. These cranes are typically used for repetitive tasks and are highly customizable for different load capacities and reach lengths.

Benefits of Small Jib Cranes in Assembly Lines

1. Improved Workflow Efficiency

Small jib cranes provide quick and easy access to tools, components, or finished goods along the assembly line. Operators can lift, rotate, and place items without needing to leave their station, reducing idle time and increasing throughput.

2. Enhanced Safety

By minimizing manual lifting and reducing strain on workers, small jib cranes help prevent common workplace injuries. Explore more on this in Small Jib Crane Safety Features to Prevent Workplace Injuries.

3. Space Optimization

Assembly lines often have narrow aisles and limited overhead clearance. A small jib crane fits seamlessly into these tight spots. For specialized setups, see Small Jib Crane Installation Tips for Narrow Work Zones.

4. Reduced Downtime

Quick installation and low maintenance requirements ensure minimal disruption to existing workflows. The simple design of small jib cranes means fewer mechanical issues and faster repairs.

Key Features to Consider for Assembly Line Use

- Rotation Range: Depending on the model, the boom can rotate from 180° to 360°, providing flexible load movement.

- Hoist Compatibility: Choose between manual, electric, or pneumatic hoists based on your application.

- Mounting Options: Wall-mounted units save floor space, while floor-mounted versions offer independent operation.

- Compact Design: Perfect for tight work zones where large cranes are impractical.

Types of Small Jib Cranes for Assembly Lines

- Wall-Mounted Articulated Jib Cranes

- Ideal for maximizing wall space and maneuvering loads around obstacles.

- See the Articulated Jib Crane – Wall Mounted option.

- Freestanding Jib Cranes

- Great for dedicated lifting zones in modular assembly layouts.

- Ceiling-Mounted Jib Cranes

- Keeps floor space clear, allowing easy movement of workers and materials.

Practical Applications in Assembly Line Settings

- Electronics Manufacturing: Transporting delicate parts between stations without human handling.

- Automotive Assembly: Positioning heavy components like engines or body panels with precision.

- Furniture Production: Lifting bulky materials like wood panels, metal frames, or upholstered sections.

Integration with Other Material Handling Tools

Small jib cranes can work in tandem with tools like:

- Suction cup systems for glass or panel handling.

- Ratchet tie-down straps to secure loads during transit.

- Larger gantry cranes for bulk material movement outside the assembly line.

Ideal for Small-Scale or DIY Workshops

Even smaller operations or home-based workshops can benefit. Explore Small Jib Crane Choices for DIY & Light-Duty Workshops for ideas.

Choosing the Right Crane Model

Factors to consider:

- Load capacity and duty cycle

- Required lifting height

- Rotation range

- Mounting surface and structural support

Need help selecting? Browse more crane products suited for your facility’s needs.

Conclusion

In assembly line operations where every second counts and space is at a premium, a small jib crane delivers a competitive edge. It streamlines workflows, protects your workforce, and maximizes space efficiency.

Whether you’re upgrading an industrial facility or setting up a compact workshop, the right crane setup can redefine productivity. Make your workflow smarter, safer, and more efficient—choose a small jib crane today.

Please log in to leave a comment.