Understanding jib crane load capacity is one of the most important steps toward safe lifting—and it becomes even more critical when you connect it to a widely used safety concept: Safe Working Load (SWL). While the term “SWL” is being replaced in many regions by Working Load Limit (WLL), Normal Working Load (NWL), or Maximum Rated Capacity (MRC), the practical goal remains the same: keep lifting operations within a verified safe limit that protects people, equipment, and compliance status.

In this article, we’ll break down exactly how jib crane load capacity relates to SWL, why those terms sometimes get confused, and what you should check to prevent overload incidents—especially in workplaces that rely on frequent lifting in confined areas, workshops, manufacturing plants, and heavy industrial facilities.

Table of Contents

Toggle1. What Is SWL (Safe Working Load) and What Does It Really Mean?

Safe Working Load (SWL) is commonly described as the maximum load a piece of equipment can lift safely under normal conditions. The term is still used widely in the UK and referenced in workplace safety guidance.

SWL has historically been linked to safety legislation such as LOLER (Lifting Operations and Lifting Equipment Regulations 1998), which requires employers to reduce lifting risks and ensure equipment is properly rated, tested, and marked.

Even where SWL is no longer the preferred term, the intent remains consistent:

✅ Identify the maximum safe limit

✅ Clearly mark that limit

✅ Ensure operators do not exceed it

✅ Account for different configurations and positions

This is especially relevant for lifting equipment where geometry changes capacity—like a jib crane where radius, boom length, and rotation can change loading conditions.

2. Jib Crane Load Capacity vs. SWL: Are They the Same?

This is where many lifting teams get confused.

✅ Jib crane load capacity

Usually refers to the crane’s rated lifting capacity (e.g., 500 kg, 1 ton, 2 ton, 5 ton). This number is defined by engineering design, manufacturer rating, and applicable standards.

✅ SWL (or WLL/NWL)

Refers to the maximum safe operating limit used for planning and safe use, often stated for:

- the crane system

- hoists and trolleys

- lifting accessories (slings, clamps, shackles)

- different configurations

- different load positions

In most cases, SWL should match or stay below the rated capacity.

Key takeaway:

👉 Jib crane load capacity is what the crane is designed to lift.

👉 SWL is what you should treat as the safe operating limit in real working conditions.

In practice, SWL may be lower than the crane’s nominal capacity once you account for real-world factors like dynamic load, rigging weight, and operating conditions.

3. Why SWL Still Matters Even If Your Country Uses WLL

Many regions now use WLL (Working Load Limit) for accessories and equipment because it aligns better with standardized load-rating systems.

However, whether your workplace says SWL or WLL, you still need:

- clear marking on equipment

- compliance with local standards

- operator awareness

- documented inspection/testing

- load planning with safety factors

Because lifting incidents usually happen not from lack of equipment—but from misunderstanding limits.

And the most common misunderstanding is assuming “crane capacity” automatically equals “safe lift.”

4. The Real Relationship: How SWL Is Determined From Jib Crane Load Capacity

To understand the relationship, think of SWL as:

The safe usable capacity after applying safety assumptions and tested limits.

A crane’s design capacity is tested and rated by manufacturers under defined conditions. Then safe limits are assigned with consideration for:

1) Structural design strength

Boom, mast, wall brackets, base plate, bearings, welds, and material grade.

2) Operating configuration

- boom length

- working radius

- rotation limits (180°, 270°, 360°)

- wall-mounted vs freestanding

3) Hoist + trolley load

A big reason why SWL and jib crane load capacity differ is that hoist and trolley weight can be included as part of the design load.

4) Dynamic effects

Loads are rarely “perfectly static.” Movement adds forces through:

- load swing

- sudden stopping/starting

- rapid hoisting

- impact loading

- rotation acceleration

So even if the crane is rated 2 tons, the safe working practice may require a margin.

5. SWL is Not Only About the Crane—It’s Also About the Whole Lift System

Here’s the most important safety reality:

✅ The actual safe limit of a lift is controlled by the weakest point in the chain.

That includes:

- the jib crane structure

- the hoist capacity

- the trolley capacity

- the sling angle and rating

- lifting clamps and attachments

- the integrity of the load itself

So jib crane load capacity may say “2 ton,” but your SWL for a specific lift could be lower depending on accessories.

This is why many safety inspections focus on lifting accessories marking as much as the crane itself.

6. What Happens If You Lift Above SWL?

Overloading can result in:

- permanent boom deflection

- anchor failure (especially wall-mounted systems)

- hoist brake slip

- structural cracking

- load drop or uncontrolled swing

- injury or fatal incidents

- compliance violations and legal consequences

This is why safe load limits are protected by regulation and enforced by audits.

If you want an in-depth breakdown of overload consequences and what to do next, read:

✅ What If Jib Crane Load Capacity Is Exceeded

7. SWL and Compliance: Why Capacity Must Be Clearly Marked

Many safety frameworks require load limits to be displayed clearly.

A key compliance issue is that lifting equipment often has different safe load limits depending on configuration. For example:

- different boom lengths

- different hook positions

- different outreach radius

- different mounting types

This matches what safety regulators often emphasize: capacity must be marked for all likely configurations.

That’s why SWL labeling is not just “good practice”—it’s part of compliance readiness.

To explore the legal and compliance angle, see:

✅ Why Jib Crane Load Capacity Is Crucial for Compliance

8. Why SWL Changes Across Applications Even With the Same Crane

Two companies can use the exact same crane model, yet operate under different SWL practices.

Why?

Because operating conditions differ:

- indoor vs outdoor wind exposure

- temperature extremes

- corrosive environments

- frequency of lifts (duty cycle)

- precision positioning vs simple loading

- load shapes (bulky vs compact)

As conditions become more challenging, safety teams may impose stricter SWL operating limits to reduce risk.

This is why SWL is often treated as a practical operational rule, not only a manufacturer rating.

Explore how application affects capacity planning here:

✅ Why Jib Crane Load Capacity Varies Across Applications

9. Best Practices: How to Use SWL Correctly in Jib Crane Operations

✅ 1) Always include rigging and attachment weight

The load on the hook is not just the product—it includes:

- clamps

- slings

- shackles

- spreader beams

- lifting devices

These items can add significant weight, especially on heavier picks.

✅ 2) Avoid dynamic shock loading

Even if the weight is within the limit, sudden starts and stops increase stress.

Encourage:

- smooth hoisting

- controlled rotation

- minimal swing

- stable load positioning

✅ 3) Inspect and test regularly

SWL is meaningful only if equipment remains in verified condition.

Routine checks should include:

- hoist brake performance

- bolt tightness

- weld inspection

- bearing lubrication

- limit switch function

- structural deformation

✅ 4) Use the right crane type for the space

In tight or obstacle-heavy zones, an articulated jib can improve positioning and reduce side loads.

A strong option for compact workstations is:

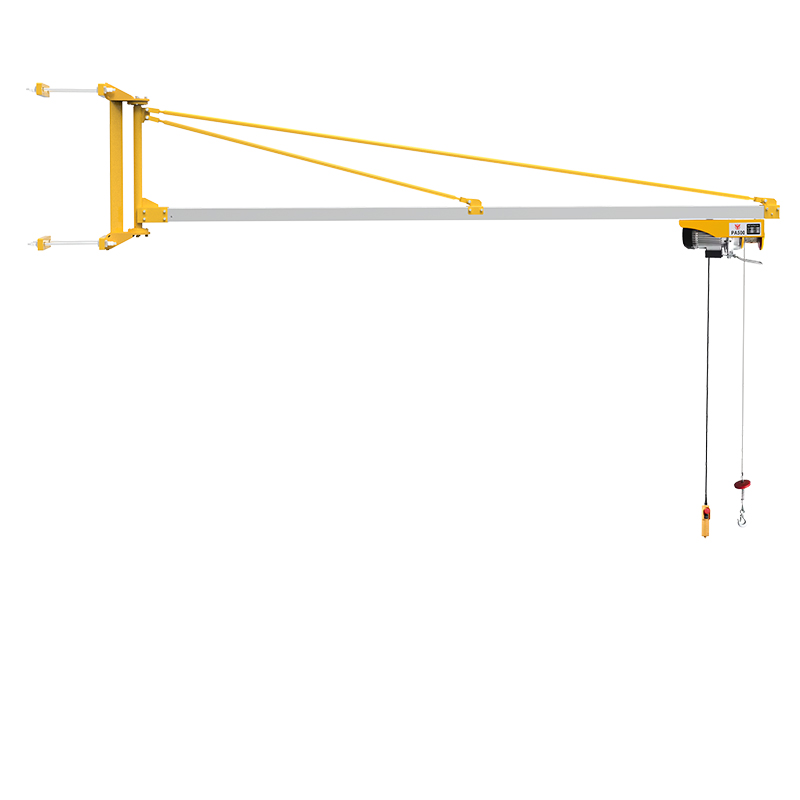

✅ Articulated Jib Crane – Wall Mounted

10. Choosing the Right Jib Crane Load Capacity Starts With SWL Thinking

Many companies select cranes by “maximum capacity,” but the smarter method is:

- Identify typical loads and heaviest loads

- Add rigging and accessory mass

- Consider lift frequency and environment

- Determine SWL requirement with safety margin

- Choose crane capacity that supports SWL without operating near its limit every day

When a crane repeatedly operates near max load, wear increases and risk rises. In most cases, a buffer improves:

- safety

- durability

- efficiency

- long-term cost savings

11. Where to Find the SWL Information

To operate safely, SWL/WLL information should be available:

- on the crane nameplate

- on hoist and trolley labels

- on accessory tags

- in the manufacturer documentation

- in your site lifting plan

You should never rely on memory—operators must verify load limits before lifting.

Conclusion: Jib Crane Load Capacity and SWL Must Work Together

Jib crane load capacity tells you what the crane is engineered to lift.

SWL (or WLL/NWL/MRC) tells you what you can lift safely in real operating conditions.

When those values are understood and followed, your workplace gains:

✅ safer lifts

✅ fewer breakdowns

✅ reduced liability

✅ stronger compliance outcomes

✅ longer equipment life

If you want to explore different jib crane models for your applications—including wall-mounted and articulated systems—browse:

✅ more crane products

Please log in to leave a comment.